Video Article Open Access

Novel Approach to Synthesis of Magnesium-Based Solids for Reversible Hydrogen Storage

Jaroslav Jerz1,*, Arun Gopinathan1,2, Jaroslav Kováčik1

1Institute of Materials & Machine Mechanics, Slovak Academy of Sciences, Bratislava, Slovakia

2Faculty of Materials Science and Technology, Slovak University of Technology, Trnava, Slovakia

Vid. Proc. Adv. Mater., Volume 3, Article ID 2208334 (2022)

DOI: 10.5185/vpoam.2022.08334

Publication Date (Web): 13 Dec 2022

Copyright © IAAM

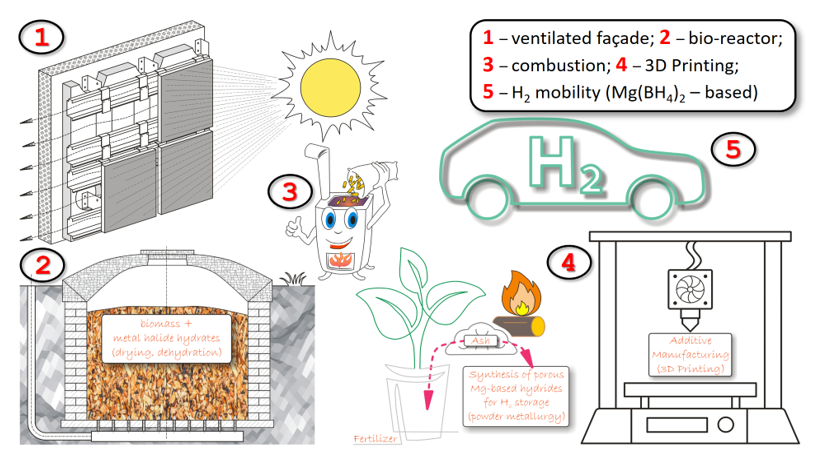

Graphical Abstract

Abstract

The technical concepts of building cladding structures used in the current construction industry are often associated with inappropriately chosen materials for façade and roofing systems. These environmentally unsuitable building solutions, therefore, causes excessive and uneven overheating of the earth’s surface by the Sun and thus strongly supports the acceleration of the current rapid climate change.

However, thermochemical sorption long-term heat storage techniques have the great potential to store vast amounts of energy in the form of low potential heat obtained from summer solar energy surpluses. This contribution describes recent advancements resulting from the possibilities of using thermochemical storage of energy in combination with extremely efficient aluminium foam heat exchangers impregnated by Phase Change Materials (PCMs) repeatedly allowing to store latent heat of phase transformation during melting and to dissipate it during solidification of PCMs to the vicinity of the heat exchanger. Besides, this paper explains the principles of simple solar energy harvesting using a thermally active heat exchanger covering the entire sloping roof of the building, which can dissipate undesirable heat to the building's surroundings during cold summer nights when the need arises. Moreover, the possibility to reduce significantly the costs of maintaining sufficient thermal comfort with the use of interior ceiling panels made of aluminium foam impregnated with PCMs has been described in this contribution.

This paper describes the practical applications of the system for storing summer solar energy surpluses based on the thermochemical reaction – dehydration of the mixture comprising metal halide hydrates and biomas, including the possibility to synthetize metal hydride powders characterized by an excellent ability to store reversibly hydrogen. The waste ash after the combustion of said mixture of dehydrated biomass and chemical compounds is used for this purpose as well. The ability to store reversibly hydrogen without structural degradation is sufficient by magnesium-based hydrides, such as Mg(BH4)2, Mg2CoH5, Mg(NH2)2, Mg(AlH4)2, etc. The breakthrough solution proposed by this contribution is based on an innovative approach of metal hydrides synthesis by powder metallurgy, by which recycled waste ash from combustion of solid biomass enriched with dehydrated metal halide hydrates is admixed during preparation of industrially viable Mg-based microporous solids for reversible hydrogen storage using additive manufacturing technique.

Keywords

Hydrogen storage; additive manufacturing; magnesium hydrides; powder metallurgy; 3D printing.

Acknowledgement

The financial support by the European Regional Development Fund under the contract NFP305010AWJ4 (project: Create synergies in the region Slovakia – Austria by sharing best practices and awareness of innovative technologies to advance digitalized manufacturing, acronym: SHARE4.0 – SK – AT from program INTERREG V-A Slovak Republic – Austria) is gratefully acknowledged.

References

- A. Gopinathan, J. Jerz, J. Kováčik, T. Dvorák, Materials, 2021, 14, 3623. ISSN 1996-1944.

- J. Jerz, A. Gopinathan, J. Kováčik, Advanced Materials Letters, 2021, 12(3), 21031612. ISSN 0976-3961.

- J. Jerz, A. Gopinathan, J. Kováčik, Video Proceedings of Advanced Materials, 2021, vol. 2, no. 210146, Article ID 2021-0146, DOI: 10.5185/vpoam.2021.0146.

- J. Jerz, A. Gopinathan, A. Puškár, D. Szabó, J. Kováčik, Structural design of thermo-active aluminium foam roofing. In: Conference Proceedings MTSM, 2021, p. 53-58. ISSN 1847-7917.

Biography

Jaroslav Jerz has completed his PhD from Vienna University of Technology (Austria) with dissertation dedicated to the development of aluminum foam by powder metallurgy. He is head of SmartGrid laboratory at the Institute of Materials & Machine Mechanics (Slovakia). His laboratory is involved in the investigation of efficient management of production and consumption of energy from renewable sources and performs also development, testing and industrial commercialization of novel ceiling aluminum foam heating/cooling panels. His scientific work is devoted to advanced metallic materials, development of technologies for their industrial production and transfer of knowledge gained by material research into industrial practice.

Video Proceedings of Advanced Materials

Upcoming Congress