Video Article Open Access

High-Resolution Extrusion Printing of Large-Flake Graphene Oxide/PEDOT: PSS Hydrogels for Advanced Electromagnetic Interference Shielding Applications

Mohammad Arjmand*, Ahmadreza Ghaffarkhah, Milad Kamkar, Saeed Ghaderi

Nanomaterials and Polymer Nanocomposites Laboratory, School of Engineering, University of British Columbia, Kelowna, BC, V1V 1V7, Canada

Vid. Proc. Adv. Mater., Volume 3, Article ID 2206283 (2022)

DOI: 10.5185/vpoam.2022.06283

Publication Date (Web): 12 Sep 2022

Copyright © IAAM

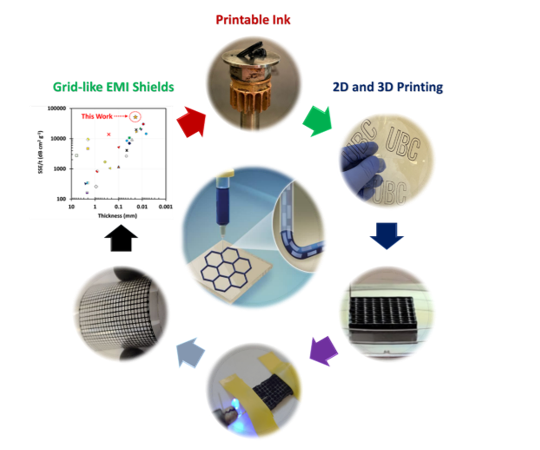

Graphical Abstract

Abstract

In modern era, electronic devices have enhanced the quality level of human lives; however, they could act as electromagnetic radiation emitters, perturbing the performance of other surrounding electronic devices, and even worse, having a negative impact on biological/living species. To address this issue, a range of promising and versatile electromagnetic interference (EMI) shields have been developed to mitigate the adverse effects of electromagnetic noises. Nevertheless, there is still much room left for further advancement in choice of materials and manufacturing technologies for developing cost-effective, flexible, high-performance EMI shields. From a materials design perspective, poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS), which is known as the superstar of intrinsically conductive polymers, is a perfect candidate for developing advanced high-performance EMI shields. PEDOT:PSS possesses many unique properties, such as good film-forming ability, exceptional electrical conductivity, flexibility, and water processability. However, fabrication of PEDOT:PSS or its nanocomposites structures mainly relies on conventional manufacturing technologies such as vacuum-assisted filtration, spin-coating, and spray coating with limitations and challenges in terms of macro-scale design. In this research study, we focused on extrusion 3D printing of PEDOT:PSS/large flake graphene oxide inks as a promising strategy for macro-scale engineering of patterned shields. Our method offers customization, reduction in material waste, and rapid production compared to conventional manufacturing technologies. We leveraged extrusion 3D printing technology to develop a novel class of micrometer-thick EMI shields that present exceptional EMI shielding effectiveness, outstanding flexibility, and minimum production cost.

Keywords

Extrusion printing; conductive ink; EMI shielding; graphene oxide, PEDOT:PSS.

Acknowledgement

The authors acknowledge the Syilx Okanagan Nation for the use of their traditional, ancestral, and unceded territory, the land on which the research was conducted. The authors acknowledge the support of the Natural Sciences and Engineering Research Council of Canada (NSERC), [funding reference number ALLRP 555586-20]. The authors appreciate the financial support provided by the University of British Columbia, the Canada Research Chairs Program, and Zentek Ltd.

References

- M. Arjmand, T. Apperley, M. Okoniewski, U. Sundararaj, Carbon, 2012, 50, 5126.

- M. Arjmand, K. Chizari, B. Krause, P. Pötschke, U. Sundararaj, Carbon, 2016, 98, 358.

- A. Ghaffarkhah, M. Kamkar, H. Riazi, E. Hosseini, Z.A. Dijvejin, K. Golovin, M. Soroush, M. Arjmand, New Journal of Chemistry, 2021.

Biography

Mohammad Arjmand is an assistant professor in the School of Engineering at the University of British Columbia, Okanagan Campus. He is also the Canada Research Chair in Advanced Materials and Polymer Engineering. Dr. Arjmand directs the Nanomaterials and Polymer Nanocomposites Laboratory (NPNL), which focuses on the synthesis and development of multifunctional nanomaterials and polymer nanocomposites. Dr. Arjmand obtained his Ph.D. from the University of Calgary in Chemical (Polymer) Engineering. After his Ph.D., he carried out postdoctoral work at the University of Calgary and the University of Toronto and was a Guest Researcher at IPF, Dresden Germany. Research Website: https://npnl.ok.ubc.ca/

Video Proceedings of Advanced Materials

Upcoming Congress