Video Article Open Access

Development of 3D Printed Natural Fiber Reinforced Composite Scaffolds for Maxillofacial Reconstruction

Sri Sai Ramya Bojedla1,*, Falguni Pati2, Mostafa Nikzad3, Syed H. Masood4

1Research scholar, Department of Biomedical Engineering, Indian Institute of Technology Hyderabad, Kandi, Sangareddy 502284, Telangana, India

2Associate Professor, Department of Biomedical Engineering, Indian Institute of Technology Hyderabad, Kandi, Sangareddy 502284, Telangana, India

3Lecturer, Department of Mechanical and Product Design Engineering, Faculty of Science, Engineering and Technology, Swinburne University of Technology, Hawthorn, Melbourne, Australia 3122

4Professor, Course Director, PG (Advanced Manufacturing Technology), Department of Mechanical and Product Design Engineering, Faculty of Science, Engineering and Technology, Swinburne University of Technology, Hawthorn, Melbourne, Australia 3122

Vid. Proc. Adv. Mater., Volume 3, Article ID 2203272 (2022)

DOI: 10.5185/vpoam.2022.03272

Publication Date (Web): 28 May 2022

Copyright © IAAM

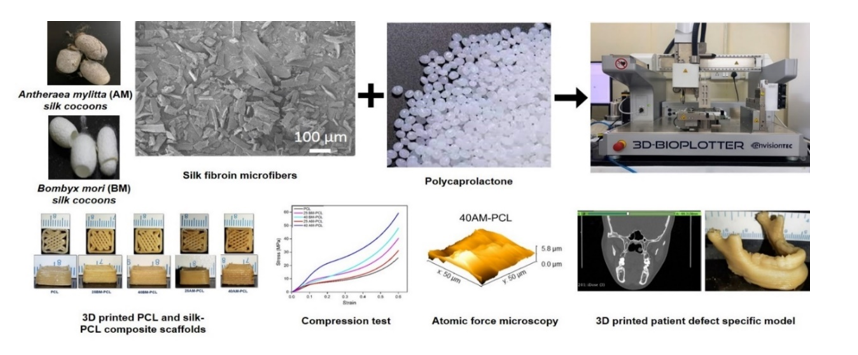

Graphical Abstract

Abstract

Nature provides the best of solutions to humans. One such incredible gift to regenerative medicine is silk. The literature has publicized a long appreciation for silk owing to its incredible physical and biological assets. Its bioactive nature, unique mechanical strength, and processing flexibility make us curious to explore further to apply it in the clinics for the welfare of mankind. In this study, Antheraea mylitta and Bombyx mori silk fibroin microfibers are developed by two economical and straightforward steps via degumming and hydrolysis for the first time, and a bioactive composite is manufactured by mixing silk fibroin microfibers at various concentrations with polycaprolactone (PCL), a biocompatible, aliphatic semi-crystalline synthetic polymer. Reconstructive surgery in any part of the body except for the maxillofacial region deals with replacing its function. But answering both the aesthetics and function is of utmost importance when it comes to facial reconstruction as it plays a critical role in the psychological and social well-being of the patient. The main concern in developing adequate bone graft substitutes or a scaffold is the noteworthy variation in each patient's bone anatomy. Additionally, the anatomical shape and size will vary based on the type of defect. The advent of additive manufacturing (AM) or 3D printing techniques to bone tissue engineering has facilitated overcoming many of the restraints of conventional fabrication techniques. The acquired patient's CT data is converted into a stereolithographic (STL)-file which is further utilized by the 3D printer to create a 3D scaffold structure in an interconnected layer-by-layer fashion. This study aims to address the limitations of currently available materials and fabrication technologies and develop a customized biomaterial implant via 3D printing technology to reconstruct complex form, function, and aesthetics of the facial anatomy. These composite scaffolds underwent structural and mechanical characterization. Atomic force microscopic (AFM) and field emission scanning electron microscopic (FESEM) images showed the uniform dispersion of the silk fibroin microfibers in the PCL matrix. With the addition of silk, there is improvement in the compressive strength of the hybrid scaffolds. The scaffolds with Antheraea mylitta silk revealed higher compressive modulus than that of Bombyx mori silk. The above results of PCL-silk scaffolds strongly recommend their utilization in bone regenerative applications. Successful completion of this research will provide a great weapon in the maxillofacial reconstructive armamentarium.

Keywords

Compressive modulus; 3D Printing; maxillofacial reconstruction; natural fibre reinforced composites; silk fibroin microfibers.

Acknowledgement

We acknowledge the financial support from DST-FIST (SR/FST/LSI-683/2016) to the Department of Biomedical Engineering, Indian Institute of Technology Hyderabad.

References

- Stanislav Evlashin, S. D.; Pavel Dyakonov, Mikhail Tarkhov, Sergey Rodionov, S. K. Anastasia Shpichka, Mikhail Kostenko, and P. T. and I. A. Ivan Sergeichev, Materials, 2019, 12, 2991.

- Liu, Xin, Bo Chen, Yan Li, Yan Kong, Ming Gao, Lu Zhong Zhang, and Ning Gu, Journal of Bioactive and Compatible Polymers, 2020, 36, 59.

- Li, Z.; Wu, N.; Cheng, J.; Sun, M.; Yang, P.; Zhao, F.; Zhang. J.; Duan, X.; Fu, X.; Zhang, J.; Hu, X.; Theranostics, 2020, 10, 5090.

- Misch, Carl E., Zhimin Qu, and Martha W. Bidez, Journal of Oral and Maxillofacial Surgery, 1999, 57, 700.

- G. H. Darshan, D. Kong, J. Gautrot, and S. Vootla, Sci. Rep., 2017, 7, 1.

Biography

Dr. B Sri Sai Ramya is a research scholar at the Indian Institute of Technology Hyderabad, India. Ramya is an oral physician and a maxillofacial radiologist by profession and a dedicated and committed researcher with almost four years of experience in field of biomedical research. She has extensive background in understanding the patients’ needs during the pre- and post-surgical maxillofacial reconstructive procedures and extensively worked and explored various aspects of implant development and characterization for maxillofacial reconstruction. She has been trained in CAD designing and modelling- CATIA and Reverse Engineering. She is working on extrusion-based 3D printing for the development of customized implants. Ramya is efficient and takes flexible approach to upgrade to the new upcoming treatment procedures.

Video Proceedings of Advanced Materials

Upcoming Congress