Video Article Open Access

High-performance Flexible Strain Sensors Fabricated by Additive Manufacturing

Dong Xiang1,*, Xuezhong Zhang1, Zixi Zhang1, Eileen Harkin-Jones2

1Southwest Petroleum University, Chengdu,610500, China

2University of Ulster, Jordanstown, BT37 0QB, UK

Vid. Proc. Adv. Mater., Volume 3, Article ID 2203260 (2022)

DOI: 10.5185/vpoam.2022.03260

Publication Date (Web): 20 Jul 2022

Copyright © IAAM

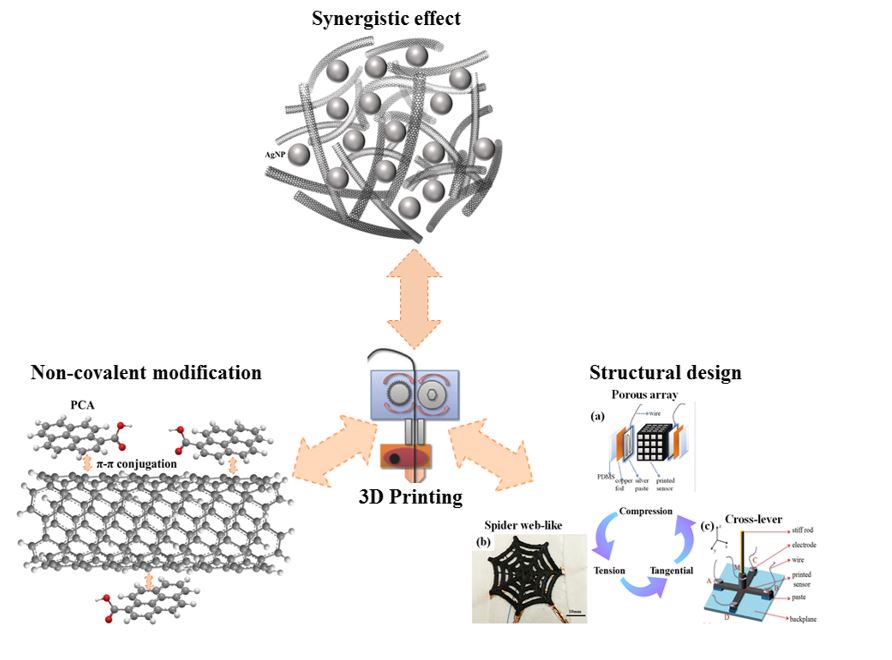

Graphical Abstract

Abstract

Flexible strain sensors based on conductive polymer nanocomposites have attracted extensive attention for their excellent flexibility and sensitivity. However, the current methods used to prepare flexible strain sensors often have some shortcomings, such as high cost, lack of flexibility in structural design and so on. With the development of additive manufacturing technology, it provides a new idea and solution for the preparation of flexible strain sensors. The flexible strain sensors with complex structure can be rapidly fabricated by additive manufacturing, but how to obtain better performance is still worthy of in-depth research. This report presents the preparation, structure characterization and performance research of different thermoplastic polyurethane (TPU) elastomer based conductive polymer nanocomposites. Based on these nanocomposites, high-performance strain sensors were prepared by fused deposition modeling (FDM), mainly including the following aspects: (1) non-covalent modification of carbon nanotubes (CNT) was conducted by introducing 1-pyrenecarboxylic acid (PCA), and the interaction between polymer and nanofillers was improved. The mechanical properties, electrical properties and strain sensing properties of the modified nanocomposites were enhanced. The printed sensor showed a high sensitivity (GF = 3.21 at 20% strain), large monitoring strain range (0 ~ 250%), excellent stability (up to 1000 loading/unloading cycles) and wide frequency response range (0.01 ~ 1 Hz). Based on the tunneling theory, the working mechanism of strain sensor was further studied. (2) The hybrid nanofillers of carbon nanotubes and silver nanoparticles (AgNP) were prepared by hydrothermal method. The synergistic effect between carbon nanotubes and silver nanoparticles was conducive to improve the dispersion of carbon nanotubes in the matrix, which further improved the sensitivity of printed CNT/AgNP/TPU strain sensor (GF = 5.97 at 20% strain). (3) A variety of piezoresistive sensors with complex structures that could be used to monitor compression, tension and tangential forces were printed, including sensors with porous array, spider web-like and cross-lever structures, and their performance was also optimized. In addition, these sensors also exhibited the ability to monitor human motion and speech, showing the application potential in customization fields such as intelligent robots, medical care and wearable electronic products.

Keywords

Strain sensors; conductive polymer nanocomposites; additive manufacturing; carbon nanotubes.

Acknowledgement

This work was supported by the National Natural Science Foundation of China (12102374), Sichuan Science and Technology Program (2021YFH0031) and International Cooperation Project of Chengdu (2019-GH02-00054-HZ).

References

- D. Xiang, X. Zhang, Y. Li, E. Harkin-Jones, Y. Zheng, L. Wang, C. Zhao, P. Wang, Composites Part B: Engineering, 2019, 176, 107250.

- D. Xiang, X. Zhang, E. Harkin-Jones, W. Zhu, Z. Zhou, Y. Shen, Y. Li, C. Zhao, P. Wang, Composites Part A: Applied Science and Manufacturing, 2020, 129, 105730.

- X. Zhang, D. Xiang, Y. Wu, E. Harkin-Jones, J. Shen, Y. Ye, W. Tan, J, Wang, P. Wang, C. Zhao, Y. Li, Composites Part A: Applied Science and Manufacturing, 2021, 151, 106665.

- X. Zhang, D. Xiang, W. Zhu, Y. Zheng, E. Harkin-Jones, P. Wang, C. Zhao, H. Li, Y. Li, Composites Science and Technology, 2020, 200, 108437.

- D. Xiang, Z. Zhang, Y. Wu, J. Shen, E. Harkin-Jones, Z. Li, P. Wang, C. Zhao, H. Li, Y. Li, Macromolecular Materials and Engineering, 2021, 306, 2100437.

Biography

Dong Xiang is currently an associate professor in the School of New Energy and Materials, Southwest Petroleum University, China. In 2011, he received his Master‘s Degree in Materials Processing Engineering from Chongqing University, China. In 2015, he obtained his PhD degree in Mechanical Engineering from Queen’s University Belfast, UK. His research interests mainly include conductive polymer nanocomposites, fiber reinforced polymer composites, flexible strain sensors and additive manufacturing. He is a fellow of Sichuan Science and Technology Collaborative Innovation Promotion Association, an expert in the review panel of dissertations for the Education Ministry of China, a guest editor of SCI journal Frontiers in Materials, an editorial board member of Plastic Industry (China), members of Society for the Advancement of Material and Process Engineering (SAMPE), Polymer Processing Society (PPS), Chinese Society for Composite Materials (CSCM) and Chinese Materials Research Society (C-MRS). He has published more than 50 papers in SCI journals (H-index: 15), authorized 14 China patents. He is the reviewer of over 20 SCI journals such as Journal of Materials Chemistry A, Composites Part A, Carbon and Polymer etc. He has made many invited reports at international and domestic academic conferences in his research field. He has led 8 scientific research projects, including National Natural Science Foundation of China (one of the most influential funds in China), Sichuan International Cooperation Project, Sichuan High-End Talent Introduction Project and so on. He promoted a deep international cooperation between Southwest Petroleum University (China) and University of Ulster (UK) based on 4 international cooperative research projects as the principal investigator.

Video Proceedings of Advanced Materials

Upcoming Congress