Video Article Open Access

Parametric Study of Effects of Knots on Flexural Behaviour of Timber Beams

Khaled Saad*, András Lengyel

Budapest University of Technology and Economics, Budapest, 1111, Hungary

Vid. Proc. Adv. Mater., Volume 3, Article ID 2203251 (2022)

DOI: 10.5185/vpoam.2022.03251

Publication Date (Web): 23 Jul 2022

Copyright © IAAM

Graphical Abstract

Abstract

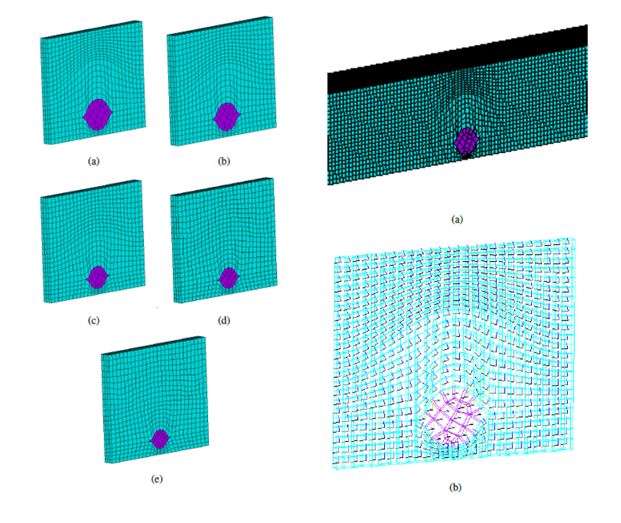

This research presents a parametric finite element study on the effects of knot characteristics (size and position) and related fibre deviations on the flexural behaviour of wood. Unlike all other similar studies, the model is not restricted to evaluating the effects of the knot diameter, diving angle, and position along the beam cross-section on the ultimate capacity of the timber beams. It can also consider the effects of the position of the knot along the beam longitudinal axis and smoothly follow the grain deviation around the knot. Moreover, a new destructive method was introduced to construct the actual three-dimensional fibre paradigm for the knot. The study revealed that the impact of the diving angle is not always positive, and it is highly dependent on its orientation. The elastic-plastic constitutive law of Nordic Spruce (Picea Abies) was considered. The influence of a conical knot’s size, position, and inclination (diving angle) on the ultimate capacity was investigated. The numerical models were experimentally validated by a four-point bending test performed on six timber beams. The ultimate loads of the beams were numerically determined based on the Tsi-Wu failure criterion. Results proved that the knot located in the tension zone causes early tensile failure and ineffective utilization of compression capacity. Knot situated at the middle of the beam in the tension zone causes a decrease of approximately 39 % in ultimate capacity with respect to the equivalent knot-free beam; moreover, recognizable reductions in the maximum capacity were reported concerning the knot diameter and position in the cross-section. However, results also showed that the knot inclination (diving angle) produces a larger ultimate capacity due to the obtained better net cross-section; nevertheless, knots oriented downward causes less net cross-section and loss in the maximum capacity.

Keywords

Timber; knot; fibre deviation; parametric finite element modeling; Norway spruce.

Acknowledgement

The presented work was conducted with the financial support of the K138615 project of the Hungarian National Research, Development, and Innovation Office. The authors wish to thank Dr Nehme Salem Georges and the Department of Construction Materials and Technologies for their full supports in conducting the experiments.

References

- Baño, V.; Arriaga, F.; Guaita, M.; Determination of the influence of size and position of knots on load capacity and stress distribution in timber beams of pinus sylvestris using finite element model. Biosystems Engineering, 2013, 114, 214-222.

- Barbero, E.J.; Shahbazi, M.; Determination of material properties for ansys progressive damage analysis of laminated composites. Composite Structures, 2017, 176, 768-779.

- Foley, C.; A three-dimensional paradigm of fiber orientation in timber. Wood Science and Technology, 2001, 35, 453-465.

- Hu, M.; Studies of the fibre direction and local bending stiffness of Norway spruce timber: For application on machine strength grading. Ph.D. Thesis. Linnaeus University Press, 2018.

Biography

A PhD candidate at the faculty of Civil Engineering at Budapest University of Technology and Economics – Department of Structural Mechanics. The research primary topic is about the finite element modeling of timber beams reinforced with carbon fibre reinforced polymers.

Video Proceedings of Advanced Materials

Upcoming Congress