Video Article Open Access

Additive Manufacturing of Spatially Configurable Heterostructured Materials

Chaolin Tan

Singapore Institute of Manufacturing Technology, A*STAR, 73 Nanyang Drive, 637662, Singapore

Vid. Proc. Adv. Mater., Volume 2, Article ID 2111249 (2021)

DOI: 10.5185/vpoam.2021.11249

Publication Date (Web): 14 May 2022

Copyright © IAAM

Graphical Abstract

Abstract

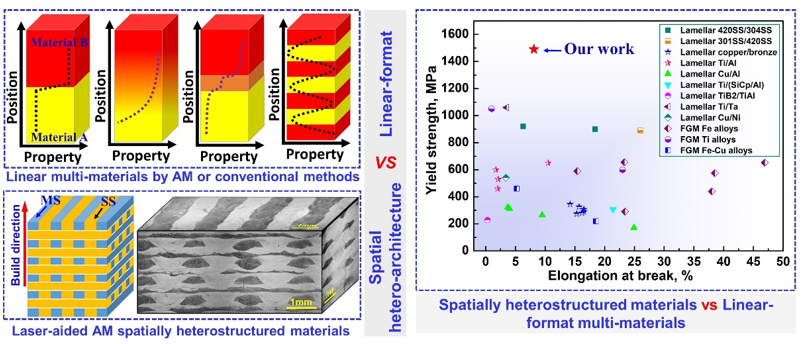

Additive manufacturing (AM) enables the processing of heterogeneous materials with customised architectures to improve strength-ductility. Current heterostructured materials demonstrate the high potential to circumvent strength-ductility trade-off but face challenges with unconfigurable hetero-zone distribution and mechanical anisotropy. This study explored laser additive manufacturing (LAM) of non-laminar spatially heterostructured materials (SHM) with configurable architectures to combine superior properties from the constitutive materials to enhance the overall properties. It is proven that the hatch spacing has a significant effect on the microstructural evolutions and mechanical properties of the SHMs as it affects the layer thickness and inter-dilution regions. The mechanical properties of the SHMs were evaluated at multi-scales. High tensile strength of about 1.6 GPa along with a reasonable break elongation of 8.1% is achieved, showing a good strength-ductility combination. Micropillar compression tests were conducted to measure localised mechanical properties, which is critical to understand the strengthening mechanism. Additionally, the SHM substantiates a much higher strength than many lamellar and linear functionally graded materials reported in the literature. This can be explained by the rule-of-mixture effect and hetero-deformation induced strengthening (HDIS). Furthermore, in-situ deformation observation reveals multiple deformation bands in SHM, which delays necking and contributes to ductility in tandem with the transformation induced plasticity (TRIP) effect. The findings highlight a novel approach for the development of SHM with a tunable performance by using LAM of multiple materials following the configurable architectures.

Keywords

Heterostructured materials; configurable architecture; strength-ductility synergy; deformation behaviour.

Acknowledgement

This work was supported by Agency for Science, Technology and Research (A*Star), the Republic of Singapore, under the IAF-PP program (Grant No: A1893a0031) and Career Development Fund (Grant No: C210112051).

References

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; Ott, R.T.; Santala, M.K.; Depond, P.J.; Matthews, M.J.; Hamza, A.V.; Zhu, T.; Nature Materials, 2018, 17, 63.

- Tan, C.; Zhang, X.; Dong, D.; Attard, B.; Wang, D.; Kuang, M.; Ma, W.; Zhou, K.; International Journal of Machine Tools and Manufacture, 2020, 155, 103592.

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; Tsuji, N.; Zhang, X.; Wu, X.; Materials Research Letters, 2020, 9, 1.

- Tan, C.; Chew, Y.; Duan, R.; Weng, F.; Sui, S.; Ng, F.L.; Du, Z.; Bi, G.; Materials Research Letters, 2021, 9, 291.

Biography

Chaolin Tan is a Research Scientist and Principal Investigator at Singapore Institute of Manufacturing Technology (SIMTech). He received his PhD degree in Materials Processing Engineering from the South China University of Technology in conjunction with University of Birmingham (UK) in 2019. He was rewarded as an Honorary Research Fellow of University of Birmingham and Guangzhou Young Talent Researcher in 2019 after graduation. He leads many national research projects of China and Singapore as the PI. His research experience in materials science and engineering, especially additive manufacturing (AM), has been over 8 years. His research experience and expertise include: (i) Additive manufacturing (AM) of Precipitation Hardening Alloys and Functional Metallic Materials (e.g., Refractory Metals, Shape Memory Alloy). (ii) AM of MMCs, Multi-materials and Heterostructured Materials, (iii) Multi-scales Microstructure Characterizations and Mechanical Properties Evaluation, and (iv) Laser Additive Manufacturing of Specific New Materials Development, Structure Design and Topography, etc. He has contributed 19 scientific papers as the first author and 3 papers as the correspondent (13 papers with IF higher than 7), with average citations exceeding 30 times in each paper. He is the editorial member of SCI journal Transactions of Nonferrous Metals Society of China and annual reviewer of many reputable journals such as Int. J. Mach. Tools Manuf., Addit. Manuf., Mater. Des., J Mater Sci Technol, etc.

Video Proceedings of Advanced Materials

Upcoming Congress