Video Article Open Access

CMC Design Chain from Testing to Modeling – Characterization and Simulation of Mechanical Behavior of Ceramic Matrix Composites

Yuan Shi

German Aerospace Center, Pfaffenwaldring 38-40, 70569 Stuttgart, Germany

Vid. Proc. Adv. Mater., Volume 2, Article ID 2110241 (2021)

DOI: 10.5185/vpoam.2021.10241

Publication Date (Web): 22 Jul 2022

Copyright © IAAM

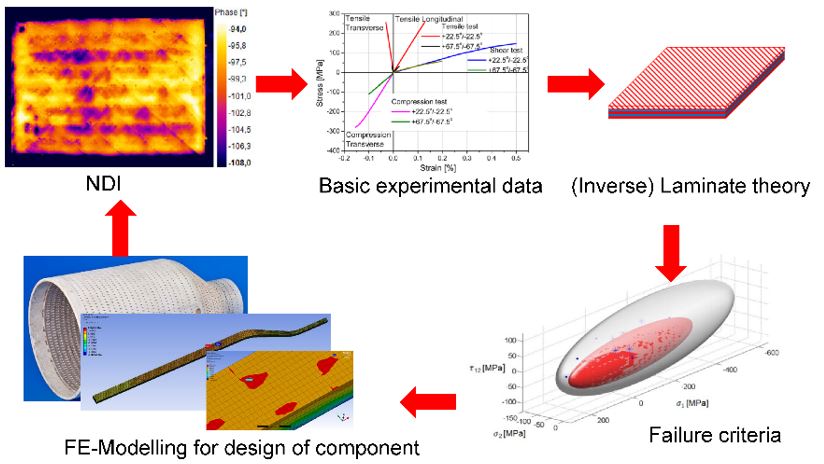

Graphical Abstract

Abstract

The application of Ceramic Matrix Composites (CMC) strongly depends on the precise prediction of the failure behaviours under real loading conditions. Therefore, a comprehensive modelling approach is necessary which describes experimental testing results dependent on microstructure and fibre orientation as well as local defects like delamination or voids. The deterministic simulation presented here is based on a design chain consisting of non-destructive investigation of microstructure, inverse laminate theory for definition of laminate properties, finite element modelling for calculation of critical stresses and strains, definition of failure criteria, and resulting failure prediction considering effects of defects. Experimental data from alloxide composite Whipox as well as from C/C-SiC processed via liquid silicon infiltration are used in order to proof the design chain. It is shown that in-plane strength and stiffness of Whipox can be predicted precisely considering any fiber orientation. The impact of interlaminar defects on failure prediction is shown on C/C-SiC composites. Here defects are implemented in the finite element model considering microstructural information from computer tomography and ultrasonic inspection. With use of fracture mechanical data damage evolution and valid failure prediction is possible and design and optimized engineering of CMC components is achievable.

Keywords

Ceramic matrix composites; design; fracture mechanics; modelling; laminate theory.

Acknowledgement

I want to thank Daniel Cepli and Raouf Jemmali at the DLR Institute of Structures and Design and Prof. Dietmar Koch at the University of Augsburg for the collaboration and support for this work.

Video Proceedings of Advanced Materials

Upcoming Congress