Video Article Open Access

Vapor Deposition to Construct Particles and Scaffolding Materials for Regenerative Medicine

Hsien-Yeh Chen1,2

1Department of Chemical Engineering, National Taiwan University, Taipei 10617, Taiwan

2Molecular Imaging Center, National Taiwan University, Taipei 10617, Taiwan

Vid. Proc. Adv. Mater., Volume 2, Article ID 2108213 (2021)

DOI: 10.5185/vpoam.2021.08213

Publication Date (Web): 21 Jul 2022

Copyright © IAAM

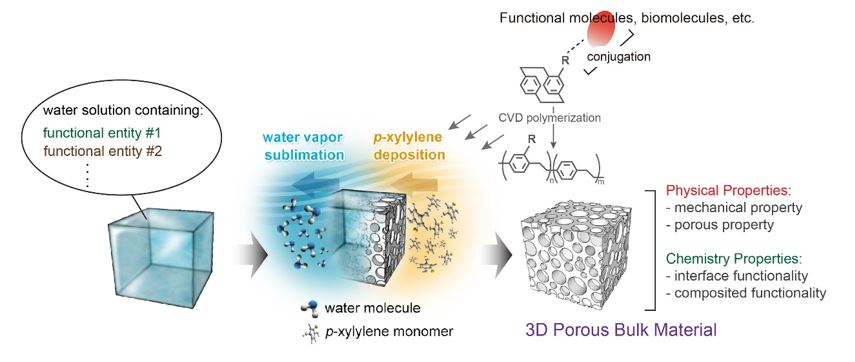

Graphical Abstract

Abstract

Functionalized poly(p-xylylenes) can be deposited via chemical vapor deposition (CVD) polymerization to generate ultra-thin films as conformal coatings and, due to the pre-defined chemical functionalities, provide a flexible solution to surface engineering challenges as they decouple surface design from bulk properties. Hence, the technology comprises essentially a one-step coating procedure to generate functionalized surfaces without requiring any kind of post-treatment once the films are deposited. Recently, three-dimensional porous structures are constructed via vapor deposition onto a sublimating solid template. Construction upon deposition of vapor-phase material occurs at a dynamic vapor–solid interface and is directed by the solid surface vanishing by sublimation. A proof-of-concept demonstration showed vapor depositions of poly-para-xylylenes on sublimating templates, including ice and mixtures with ethanol and hexane. The material construction macroscopically produces a replica architecture of the parent template. Characteristics of the pore structures are formed during the construction process as a result of the gas vapor and the space that is vacated by sublimation, thus enabling control of the porosity through regulation of the sublimation speed and/or the thermodynamic properties of the templates. The technology introduced herein provides a novel approach for 3D porous material manufacturing and overturns the notion that vapor deposition necessarily forms dense thin films on substrates. Applications of using the vapor sublimation and deposition process were demonstrated for the productions of hierarchical micro- and nano-particles and shaped scaffolding materials with customizable interface and bulk properties, and potentials of applying these materials for regenerative medicine were also highlighted.

Keywords

Biomaterials; vapor deposition polymerization; biomolecular engineering; porous materials.

Acknowledgement

This research was funded by the Ministry of Science and Technology of Taiwan (MOST 108‐2221‐E‐002‐169‐MY3; 108‐2218‐E‐007‐045; 109‐2314‐B‐002‐041‐MY3; 109‐2634‐F‐002‐042).

References

- Wu et al., ACS Applied Bio Materials, 2020, 3, 7193.

- Chiu et al., Chemistry of Materials, 2020, 32, 1120.

- Tung et al., Nature Communications, 2018, 9, 2564.

Video Proceedings of Advanced Materials

Upcoming Congress