Video Article Open Access

Dissolving Polymers that are not meant to dissolve

Paschalis Alexandridis

Department of Chemical and Biological Engineering, University at Buffalo, The State University of New York (SUNY), Buffalo, NY 14260-4200, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2105189 (2021)

DOI: 10.5185/vpoam.2021.05189

Publication Date (Web): 17 Sep 2021

Copyright © IAAM

Graphical Abstract

Abstract

Solvent resistance, or resistance to solvent swelling and dissolution, is a highly desirable property of many semicrystalline polymers, which enables their applications as structural materials, containers of liquids (including food and drinks, but also fuel and chemicals), surface protection, membranes, and textiles. At the same time, the recalcitrance to dissolution hinders the processing of semicrystalline polymers. This presents a limiting factor in our ability to recover valuable polymers from biomass and plastic waste. Thus, there is both a need and an opportunity to develop environmentally responsible solvents and processes capable of dissolving polymers that are not meant to dissolve.

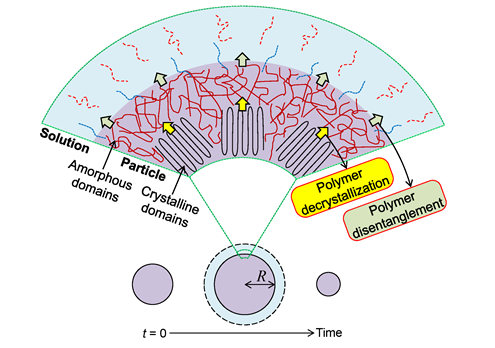

To this end, a phenomenological model is presented that captures the phenomena governing the dissolution of semicrystalline polymers, e.g., solvent diffusion, transformation from crystalline to amorphous domains, specimen swelling, and polymer chain untangling. The model is validated for the case of cellulose (cotton) fiber swelling and dissolution in various solvents. A parametric sensitivity analysis is carried out to assess the impact of various parameters on the dissolution of cellulose fibers. To emulate large-scale processing of cellulosic biomass where the particles exhibit a distribution of size and degree of crystallinity, a model is developed in which the behavior of a population of particles is obtained from an ensemble of individual polymer particle dissolution models. Using this population ensemble model, various particle size distributions are analyzed for different dissolution parameters.

The insights obtained from these studies would be useful for the rational selection of solvent systems and design of processes for the large-scale dissolution, fractionation, and reprecipitation of semicrystalline polymers such as cellulose and polyethylene, with benefits toward biomass and plastic waste valorization.

Keywords

Dissolution; precipitation; crystalline polymer; biomass; plastic recycling.

Acknowledgement

A big part of this work forms the PhD dissertation of Dr. Mohammad Ghasemi, coadvised by Prof. Marina Tsianou at the University at Buffalo. We thank the U.S. National Science Foundation (Grants CBET-1159981 and EFRI-2029375) for supporting this research.

Biography

Paschalis Alexandridis is a Distinguished Professor in the Department of Chemical and Biological Engineering with an affiliate appointment in the Department of Civil, Structural and Environmental Engineering at the University at Buffalo, The State University of New York (SUNY), where he has served as Director of Graduate Studies in Chemical Engineering, co-Director of the Materials Science and Engineering program, and Associate Dean for Research and Graduate Education in the School of Engineering. He holds a PhD in chemical engineering from MIT and has carried out postdoctoral research in polymer physical chemistry at Lund University in Sweden.

Alexandridis is an expert on soft matter and complex fluids, with research interests that bridge molecular organization to mesoscale structure, and translate these into the formulation and processing of products in a manner that is environmentally responsible and energy-efficient. Ongoing research addresses emerging problems concerning PFAS removal, biomass utilization, and plastics recycling. He has authored over 170 journal articles published in 60 different journals (Google Scholar citations >19,500 and h-index = 71) and 6 US patents on pharmaceutical formulations, superabsorbent polymers, and nanomaterial synthesis. A dedicated educator, Alexandridis has mentored in research over 75 graduate and 75 undergraduate students.

Alexandridis is a Fellow of the American Institute of Chemical Engineers (AIChE), the Royal Society of Chemistry (RCS), and the American Association for the Advancement of Science (AAAS), and has served as chair of AIChE Area 1C: "Interfacial Phenomena" and on the executive committee of the American Chemical Society (ACS) Division of Colloid and Surface Chemistry. He is currently serving as Editor-in-Chief of the Journal of Dispersion Science and Technology, co-Editor-in-Chief of the International Journal of Molecular Sciences, and Review Editor of the Journal of Surfactants and Detergents.

Video Proceedings of Advanced Materials

Upcoming Congress