Video Article Open Access

Direct Thermal Charging Cell for Low-Grade Heat to Electricity Conversion

Shien-Ping Feng* , Xun Wang , Yu-Ting Huang , Kaiyu Mu

Mechanical Engineering, The University of Hong Kong, Hong Kong

Vid. Proc. Adv. Mater., Volume 2, Article ID 2105177 (2021)

DOI: 10.5185/vpoam.2021.05177

Publication Date (Web): 29 Jul 2021

Copyright © IAAM

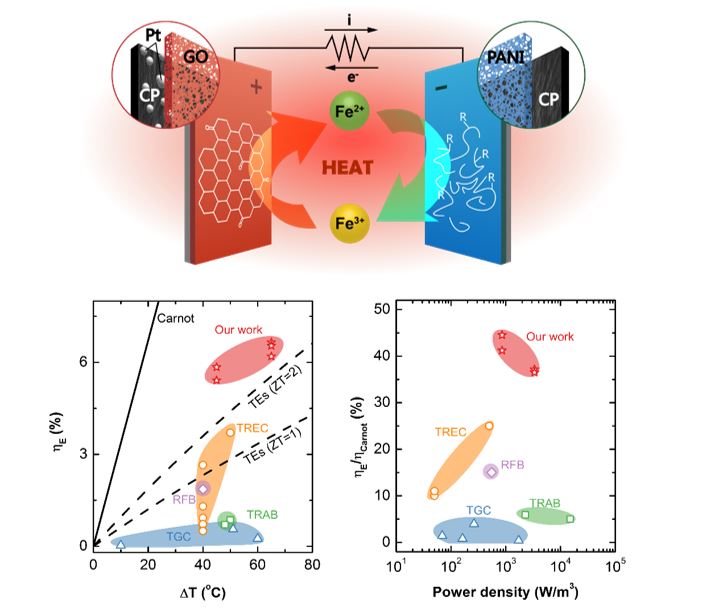

Graphical Abstract

Abstract

The energy crisis and environmental pollution have stimulated researchers around the world to explore new energy sources and develop environmentally friendly energy conversion technologies. In the process of converting primary energy into useful energy, over 60% is discharged to the environment in the form of waste heat, which involves a vast amount of low-grade heat below 100oC. Low-grade heat recovery will significantly help reducing greenhouse gas emission and bring tangible economic and environmental benefits. The low-grade waste heat, which is abundantly available in the environment and even in human body, can provide an unlimited new energy source, while current technologies to fulfil heat-to-electricity conversion are still far from optimum. The thermopower (𝛼= 𝑉/

𝑉/ 𝑇, V is the electrode voltage, T is the temperature) of conventional thermoelectric (TE) semiconductors is in a scale of 100-200 μV K-1, generating a low voltage when the temperature difference is small [1]. As a result, to produce a useful voltage of 1-5 V in low-grade heat regime requires either challenging integration of thousands of TE materials or DC-DC booster to increase the voltage, which decrease the system reliability and increase the total cost due to the complexity. Liquid-based thermoelectrochemical cells (TECs) are attractive as their 𝛼 is one order of magnitude higher than those of TEs [2]. The incorporation of an electrochemical system also offers new opportunities to engineer the entropy change, thermal and electrical transport. However, the current TEC systems are either too costly or complicated, or too low in efficiency for economical deployment. This work reported a revolutionary electrochemical system named direct thermal charging cell (DTCC), using asymmetric electrodes of a graphene oxide (GO)/platinum nanoparticles (PtNPs) cathode and a polyaniline anode (PANI) in aqueous Fe2+/Fe3+ redox electrolyte via isothermal heating operation [3,4,5]. When heated, the cell generates voltage via a thermo-pseudocapacitive effect of GO and then discharges continuously by oxidizing the PANI anode and reducing Fe3+ to Fe2+ under isothermal heating on cathode side till Fe3+ depletion. The energy conversion works continuously under isothermal heating during the entire charge and discharge process. The system can be self-regenerated when cooled down. The synergistic chemical regeneration mechanism allows the device cyclability. DTCC achieves a high 𝛼 of 5.0 mV K-1 and the high energy conversion efficiency over 5% (>30% of Carnot efficiency), which is at the forefront performance compared with the existing TECs and TEs in the low-grade heat regime. This is the first demonstration of heat-to-electricity conversion undergoing isothermal heating and chemical regeneration, which revolutionizes the design of thermoelectrochemical systems; it is fundamentally different from the state-of-the-art technologies with power generation coupled to temperature differential. Additionally, it is a simple system with the basic unit sized only 1.5 sq.cm and thickness 1 to 1.5 mm. The cell is bendable, stackable, and low cost. This technology is expected to open new horizons for many applications. Currently, our team is collaborating with industrial partners to produce integrated prototypes with DTCC modules for recycling low-grade heat in various applications (e.g., air conditioners), with the aim of demonstrating the feasibility of commercialization.

𝑇, V is the electrode voltage, T is the temperature) of conventional thermoelectric (TE) semiconductors is in a scale of 100-200 μV K-1, generating a low voltage when the temperature difference is small [1]. As a result, to produce a useful voltage of 1-5 V in low-grade heat regime requires either challenging integration of thousands of TE materials or DC-DC booster to increase the voltage, which decrease the system reliability and increase the total cost due to the complexity. Liquid-based thermoelectrochemical cells (TECs) are attractive as their 𝛼 is one order of magnitude higher than those of TEs [2]. The incorporation of an electrochemical system also offers new opportunities to engineer the entropy change, thermal and electrical transport. However, the current TEC systems are either too costly or complicated, or too low in efficiency for economical deployment. This work reported a revolutionary electrochemical system named direct thermal charging cell (DTCC), using asymmetric electrodes of a graphene oxide (GO)/platinum nanoparticles (PtNPs) cathode and a polyaniline anode (PANI) in aqueous Fe2+/Fe3+ redox electrolyte via isothermal heating operation [3,4,5]. When heated, the cell generates voltage via a thermo-pseudocapacitive effect of GO and then discharges continuously by oxidizing the PANI anode and reducing Fe3+ to Fe2+ under isothermal heating on cathode side till Fe3+ depletion. The energy conversion works continuously under isothermal heating during the entire charge and discharge process. The system can be self-regenerated when cooled down. The synergistic chemical regeneration mechanism allows the device cyclability. DTCC achieves a high 𝛼 of 5.0 mV K-1 and the high energy conversion efficiency over 5% (>30% of Carnot efficiency), which is at the forefront performance compared with the existing TECs and TEs in the low-grade heat regime. This is the first demonstration of heat-to-electricity conversion undergoing isothermal heating and chemical regeneration, which revolutionizes the design of thermoelectrochemical systems; it is fundamentally different from the state-of-the-art technologies with power generation coupled to temperature differential. Additionally, it is a simple system with the basic unit sized only 1.5 sq.cm and thickness 1 to 1.5 mm. The cell is bendable, stackable, and low cost. This technology is expected to open new horizons for many applications. Currently, our team is collaborating with industrial partners to produce integrated prototypes with DTCC modules for recycling low-grade heat in various applications (e.g., air conditioners), with the aim of demonstrating the feasibility of commercialization.

Keywords

Low grade heat; thermoelectric; thermoelectrochemical.

Acknowledgement

The authors acknowledge the financial support of General Research Fund of the Research Grants Council of Hong Kong Special Administrative Region, China under Award Number 17204516 and 17206518, and Innovation and Technology Fund (Ref: ITS/171/16FX).

References

- D. Kraemer, B. Poudel, S. P. Feng, J. C. Caylor, B. Yu, X. Yan, Y. Ma, X. Wang, D. Wang, A. Muto, K. McEnaney, M. Chiesa, Z. F. Ren, G. Chen, Nature Materials, 2011, 10, 532.

- L. Zhang, T. Kim, N. Li, T.J. Kang, J. Chen, J.M. Pringle, Advanced Materials, 2017, 29, 12.

- X. Wang, Y. T. Huang, C. Liu, K. Mu, K. H. Li, S. Wang, Y. Yang, L. Wang, C. H. Su, S. P. Feng, Nature Communications, 2019, 10, 4151 (Featured in Editors' Highlights).

- K. Mu, X. Wang, K.H. Li, S.P. Feng, Journal of Visualized Experiments (JoVE), 2020, 156, e60768.

- S. P. Feng, X. Wang, Y. T. Huang, Z. Zheng, L. Wang, K. H. Li, K. Mu, US Appl. 62/617514, PCT/CN2019/071777, TW 201935723.

Biography

Shien-Ping Feng is an Associate Professor of Mechanical Engineering at The University of Hong Kong (HKU). He received his BS, MS, PhD from National Tsing Hua University, Taiwan. Before entering academia, he was an engineer and manager at Taiwan Semiconductor Manufacturing Company from 2001 to 2008 and a deputy director at Tripod Technology Corporation from 2008 to 2009. He was employed as a Postdoctoral Associate at Massachusetts Institute of Technology from 2009 to 2011. He joined HKU as an Assistant Professor in October 2011 and was promoted to Associate Professor with tenure in September 2017. His research focuses on the development of electrochemical technology for low-grade heat recovery, solar and indoor light harvesting, and nanomaterial fabrication. Dr. Feng’s research has been well funded by external competitive grants as well as industry from Hong Kong, China, Taiwan and USA. He has published 107 journal papers and 4 conference papers. He holds 21 patents. Through his patented technologies, Dr. Feng and his team established two start-up companies. Dr. Feng received the HKU Research Output Prize and Faculty Knowledge Exchange Award, the Silver Medal Award at the 2nd Asia Exhibition of Inventions, the Gold Medal Award and Top 10 Best Invention Award at the 5th International Invention Innovation Competition in Canada (iCAN), the Business Start-up Award and Energy Award at the IChemE Global Awards, and the Gold Medal Award at the 48th International Exhibition of Inventions Geneva (2021 Special Edition). He is a Chartered Engineer (CEng), a Chartered Scientist (CSci), a Fellow (FIMMM) of the Institute of Materials, Minerals & Mining, and a Fellow (FRSC) of the Royal Society of Chemistry.

Video Proceedings of Advanced Materials

Upcoming Congress