Video Article Open Access

Promising Future of Simplified Macroalgae Biopolymer Processing Technique for Green Material Applications

Abdul Khalil H.P.S.

School of Industrial Technology, Universiti Sains Malaysia, 11800, Penang, Malaysia

Vid. Proc. Adv. Mater., Volume 2, Article ID 2103168 (2021)

DOI: 10.5185/vpoam.2021.03168

Publication Date (Web): 27 Jul 2021

Copyright © IAAM

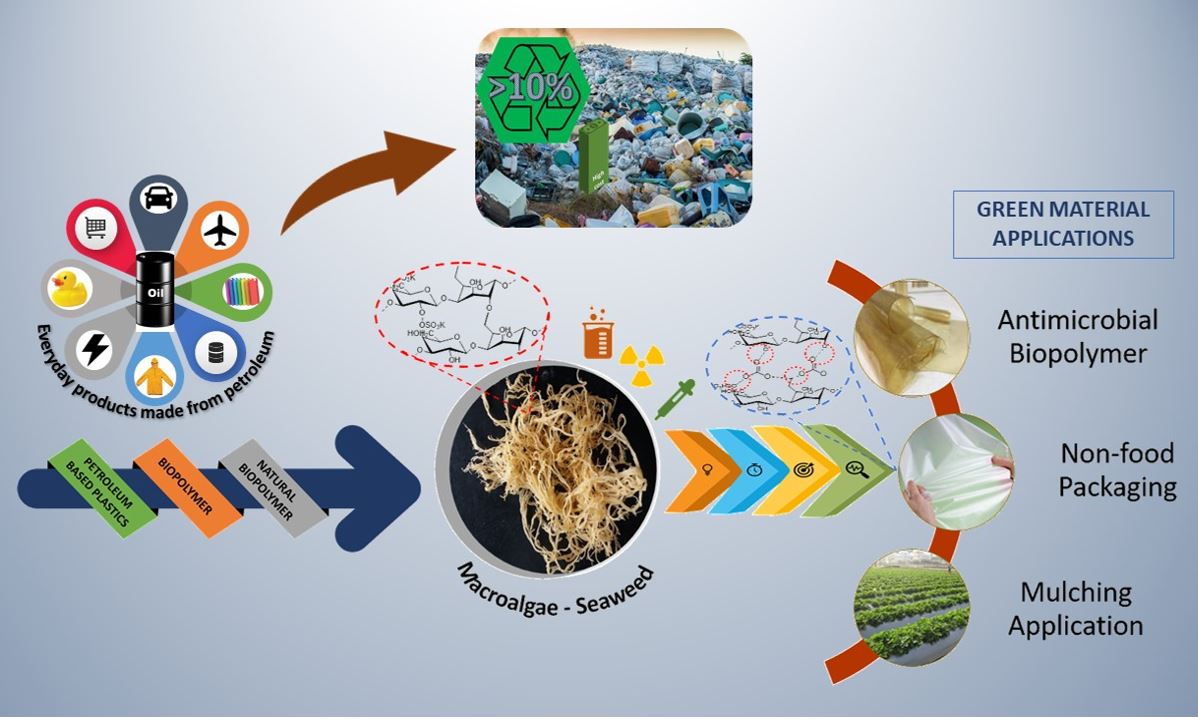

Graphical Abstract

Abstract

Synthetic plastic waste pollution has become a global challenge in both land and aquatic habitat. Statistics showed that conventional plastic had exceeded 350 million tons per year globally, but only less than 10 % can be recycled and the remaining result in waste occupying landfills and ocean [1]. Plastic waste pollution has been projected to escalate to 12 billion tons by 2050, contributing to 15% of the global carbon budget [2]. Asia has an average of 121 million tons of plastic waste have been reported each year till 2019 [3]. An average of approximately 1 million tons of plastic waste is generated in Malaysia annually. Researchers across the globe have extensively studied various types of biodegradable materials from both natural and synthetic based sources. Among these natural bio-based biopolymers, macroalgae (e.g., seaweeds) has been of significant interest in recent years due to the several advantages over other terrestrial plants. Seaweeds can grow 30 times faster than the terrestrial plants for its cultivation. Seaweeds contain unique phycocolloids that enable them to form a gel but unfortunately, the hydrophilic nature of seaweed has been an obstacle to its advancement in applications. The hydrophilic nature of seaweed biopolymer can be significantly enhanced with physical, mechanical, and chemical methods. The physical technique using gamma irradiation confirmed the intermolecular bonding enhancement between the matrix and the filler which help to improve surface hydrophobicity. The enhancement on seaweed biopolymer properties also can be achieved via mechanical techniques through the addition of organic biofillers. Whilst, the chemical treatment using coupling agent treatment (e.g. silane) help to modify the hydroxyl functional group to reduce the hydrophilicity of seaweed biopolymer. In general, all these techniques enhance the tensile, thermal and water barrier properties of the film. This, in turn, extends the feasibility of using seaweed in special applications such as agricultural mulching, dry food, and non-food packaging. More studies including the application of seaweed in biomedical applications have been done extensively. Seaweed has been chosen due to its availability and biodegradability properties. This lecture first critically underlines the recent issues on conventional plastics, bio-based plastics and associated challenges of macroalgae-based materials. After that, this presentation highlighted the achievement of the research works that we have done to combat this issue with different modifications and process techniques. Conclusive evidence of processed materials and their potential application is adequately showcased.

Keywords

Macroalgae; Green materials; Biopolymer; Sustainable packaging; Cellulose fibres.

Acknowledgement

All the authors are gratefully acknowledged Ministry of Higher Education for the Fundamental Research Grant Scheme – Malaysia’s Research Star Award 2015 (FRGS-MRSA 203-6711837).

References

- Folino, A., Karageorgiou, A., Calabrò, P.S. and Komilis, D., Sustainability, 2020, 12(15), p.1-37.

- Silva, A.L.P., Prata, J.C., Walker, T.R., Campos, D., Duarte, A.C., Soares, A.M., Barcelò, D. and Rocha-Santos, T., Science of the Total Environment, 2020, 742, p.1-8

- Liang, Y., Tan, Q., Song, Q. and Li, J., Waste Management, 2020, 119, p. 242-253

- Nasir, N.N. and Othman, S.A., Journal of Advanced Research in Materials Science, 2020, 74(1), p.19-28.

Biography

Prof. Ts. Datuk Dr. Abdul Khalil Shawkataly, F.I.M.M.M., U.K., (Abdul Khalil, H.P.S.). He holds a Doctor of Philosophy (Biofiber and Biocomposite) Degree from the University of Wales, United Kingdom. He has served at Universiti Sains Malaysia (USM) for 28 years since 1992 and is currently a Senior Professor at the School of Industrial Technology (PPTI), USM. His areas of expertise include biocomposite, bioplastic, and nanocellulose based materials. These three fields are emphasizing on biomass raw materials in biodegradable advanced applications. He is a Fellow of international academic professional associations, The Institute of Materials, Minerals, and Mining (F.I.M.M.M), United Kingdom. He was the recipient of the 13th National Academic Award, Malaysia (AAN) in 2019, Malaysia’s Research Star Award (MRSA) 2018 and 2019 for High Impact Paper in The World in Elsevier, Scopus and Malaysia Rising Star Award (Thomson & Reuters) in 2015. At the national and institutional levels, he has many achievements and successful research, publication, administration, and committee heads. He was the Advisor Panel of Malaysian Citation Centre, Ministry of Education; Research Fellow at Institute of Forestry and Forest Product; Standards Malaysia (MS) National Committee for Wood-Based Panels. He was awarded as the Top Research Scientists in Malaysia (TRSM) from the Academy of Science since 2014. He was appointed as Academic World Class Professor by the Ministry of Education and Culture, Indonesia for 2018, 2019 and 2020. He had been appointed as an editorial board of five Scopus/ISI journals. As an expert researcher in his field, he has reviewed more than 250 articles in reputable journals. To date, he has published over 300 scientific articles in Scopus with an H-Index of 45 and over 9,500 citations. He also excellently published 3 academic books, 50 chapters in book and 4 non-academic books (community/coffee table books).

Video Proceedings of Advanced Materials

Upcoming Congress