Video Article Open Access

Design and Processing of Biocompatible Ti alloys for Bone Implant Applications

J. Eckert1,2

1Erich Schmid Institute of Materials Science, Austrian Academy of Sciences, A-8700 Leoben, Austria

2Department of Materials Science, Montanuniversität Leoben, A-8700 Leoben, Austria

Vid. Proc. Adv. Mater., Volume 2, Article ID 202108220 (2021)

DOI: 10.5185/vpoam.2021.08220

Publication Date (Web): 20 Mar 2022

Copyright © IAAM

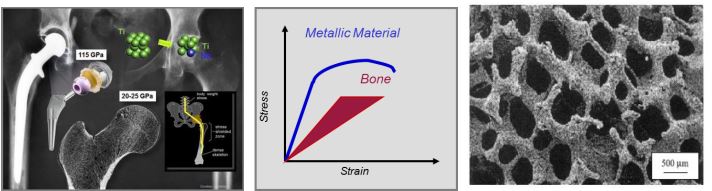

Graphical Abstract

Abstract

All forms of the research contribution at the conference must be accompanied by an abstract. In brief, the abstract should concisely describe the purpose of the research, indicate the experimental procedures used, summarize the key findings, and focus on the major conclusions. Abstract should be in one paragraph. Metallic materials with tailored properties are crucially important for a variety of biomedical applications related to trauma and orthopedic surgery. There is a strong need not only for successful development of new high-performance alloys but also for elaborating suitable processing routes enabling control over phase and microstructure selection, and optimization of the related physical and mechanical properties.

This talk will present recent results obtained for Ti-based alloys and composites with modulated length-scale of microstructural features and constituent phases that are promising for implant applications. Along this line, metastable Ti–Nb alloys have received a constantly growing attention in the on-going development of novel metallic materials for hard tissue replacement and repair as well as in the search for new Ni-free Ti-based shape memory and/or superelastic alloys [1-4]. The performance of a load-bearing orthopedic implant is largely determined by its stiffness [1]. This depends on the elastic moduli of the material and on the shape and size of the implant. To prevent loosening of the implant caused by stress-shielding of the surrounding bone tissue, the implant should have a low stiffness and a respectively low elastic modulus [1,2]. Whereas most of the current research focused on the search for biocompatible low-modulus alloys is set on beta-type Ti-based materials, the potential of fully martensitic Ti-based alloys remains largely unexplored. This work will consider the phase formation and the mechanical behavior of binary Ti–Nb alloys (Nb = 16 ÷ 31 wt.%).

Examples for the techniques and process variables employed for synthesis of bulk and porous structures will be described and correlated with the resulting phases, microstructures and properties. These techniques include casting, quenching under non-equilibrium conditions as well as mechanical attrition, severe plastic deformation and thermo-mechanical processing for the synthesis of metastable materials, powder consolidation to create bulk or porous specimens with the desired microstructure and properties, and additive manufacturing for fabrication of parts with intricate and complex geometries. Experimental data for the resulting structures obtained by non-equilibrium processing will be presented for selected ultrafine-grained or nanostructured alloys, and the mechanisms responsible for phase and microstructure formation and the related properties will be discussed in order to derive guidelines for optimized alloy design and tailoring of properties.

Keywords

Biocompatible Ti alloys, alloy design, processing, fabrication, property optimization.

Acknowledgement

This work was supported by the European Commission within FP7/2007–13 under the grant agreement no. 264635 (BioTiNet-ITN). It further benefited from financial support by the German Science Foundation within SFB/Transregio 79, the Austrian Science Fund FWF in the framework of Research Project P26729-N19 and the ERC Advanced Grant INTELHYB (ERC-2013-ADG-340025).

References

- M. Niinomi, M. Nakai, J. Hieda, Acta Biomaterialia, 2012, 8, 3888.

- T. Hanawa, Science and Technology of Advanced Materials, 2012, 13, 064102.

- S. Miyazaki, H.Y. Kim, H. Hosoda, Materials Science and Engineering A 2006, 438-440, 18.

- M. Bönisch, T. Waitz, M. Calin, W. Skrotzki, J. Eckert, International Journal of Plasticity 85, 2016, 85, 190.

Biography

Jurgen Eckert, is Director of the Erich Schmid Institute (ESI) of Materials Science of the Austrian Academy of Sciences and Head of the Department Materials Physics at Montanuniversität Leoben, Austria and Professor at Dresden University of Technology, Germany. He is coauthor of more than 1100 scientific papers and has 20 patents in the areas of materials science and processing technology. He is member of editorial board of Materials Today Advances. He received several honours and awards such as the Gottfried Wilhelm Leibniz Award of the German Research Foundation, an ERC-Advanced Grant of the European Research Council, the ISMANAM Senior Scientist Award, the Hsun Lee Lecture Award of the Chinese Academy of Sciences, the DGM Georg-Sachs-Prize etc.

Video Proceedings of Advanced Materials

Upcoming Congress