Video Article Open Access

Progress in Developing Robust Ceramic Thin Film Materials

Paul H. Mayrhofer

Institute of Materials Science and Technology, TU Wien University, Vienna, 1060, Austria

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-03162 (2021)

DOI: 10.5185/vpoam.2021.03162

Publication Date (Web): 08 May 2021

Copyright © IAAM

Graphical Abstract

Abstract

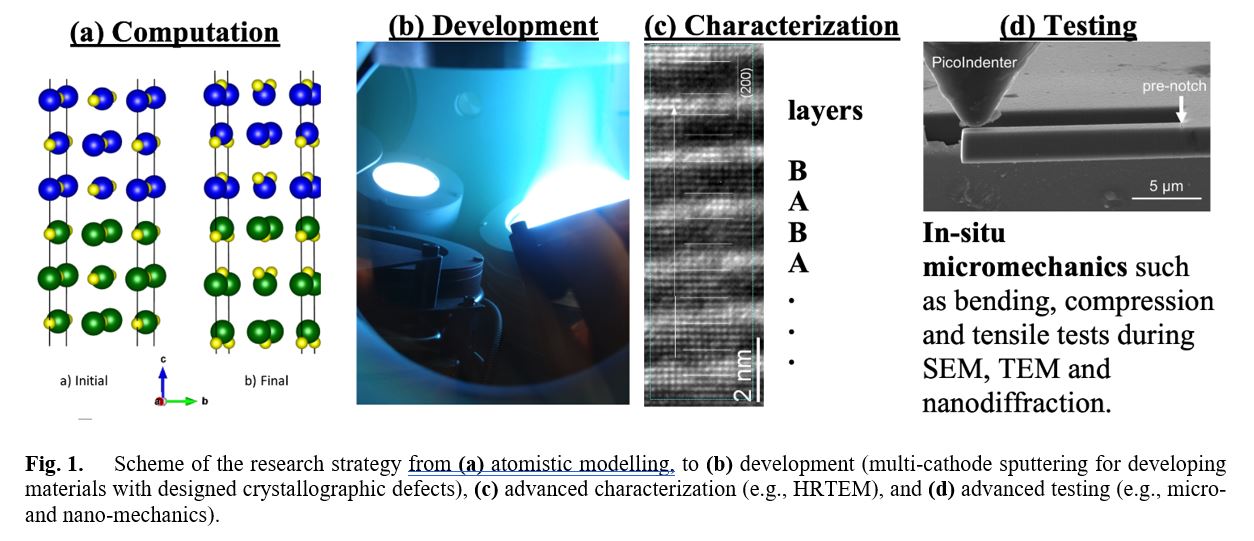

As the demands on machining tools and engineering components continuously increase, robust protective coatings are increasingly important. Whenever mechanical attack is dominating the loading profile of materials, the combination of high strength and fracture toughness is required. Nitrides but especially diborides are excellent candidates for exceptionally high strength (with hardness even above 40 GPa) to withstand high mechanical loading. However, their fracture resistance is rather limited, with typical KIC values of ~3 MPa√m for nitrides and ~1 MPa√m for diborides (obtained by in-situ micromechanical bending tests of free-standing coating materials).

We will use recent developments – where we applied alloying and architecture concepts (e.g., composition and/or phase modulated layers) to transition metal nitrides and borides, for optimizing their properties – to derive important materials design guidelines for improved strength, ductility, but also stability. The coatings were prepared by physical vapor deposition (magnetron sputtering as well as arc evaporation) and investigated by X-ray diffraction, transmission electron microscopy, nanoindentation (for hardness and indentation modulus), and in-situ micromechanical bending tests (for fracture toughness). Especially Ta proved to be an extremely versatile alloying element, able to increase strength but also ductility, as well as thermal stability and oxidation resistance of Ti-Al-N coatings for example, belonging to this still extremely important material class. This allowed the development of Ti-Al-Ta-N coatings with H ~35 GPa combined with KIC ~4.7 MPa√m and superior oxidation resistance. Tantalum also helps the rather brittle diborides to combine high hardness with toughness as shown for W-Ta-B2 exhibiting H ~42 GPa and KIC ~4.0 MPa√m. With the help of various superlattice coatings, we further show that through such architectural concepts, strength and ductility (here, basically obtained by in-situ micromechanical cantilever bending tests) can be improved simultaneously.

The individual concepts allow the design of materials to meet the ever-growing demand for protective coatings tailor-made for specific applications.

Keywords

PVD coatings; phase stability; hardness; toughness; oxidation resistance.

Acknowledgement

The Austrian Science Fund FWF (projects P30341, Y371) and the Austrian Federal Ministry of Economy, Family and Youth and the National Foundation for Research, Technology and Development (through the Christian Doppler Laboratory Application Oriented Coating Development) is highly acknowledged for financial support. We also acknowledge the use of facilities of USTEM and XRC at TU Wien.

References

- M. Schlögl, C. Kirchlechner, J. Paulitsch, J. Keckes, P.H. Mayrhofer, Effects of structure and interfaces on fracture toughness of CrN/AlN multilayer coatings, Scripta Mat. 68, 2013, 917

- R. Hahn, M. Bartosik, R. Soler, C. Kirchlechner, G. Dehm, P.H. Mayrhofer, Superlattice effect for enhanced fracture toughness of hard coatings, Scripta Mat. 124, 2016, 67.

- H. Asanuma, F.F. Klimashin, P. Polcik, S. Kolozsvári, H. Riedl, P.H. Mayrhofer, Hard Ti-Al-N endowed with high heat-resistance through alloying with Ta and Ce, Surf. Coat. Technol. 372, 2019, 26

- C. Fuger, V. Moraes, R. Hahn, H. Bolvardi, P. Polcik, H. Riedl, P.H. Mayrhofer, Influence of Ta on phase stability and mechanical properties of WB2, MRS Commun. 9(1), 2019, 375.

- J. Buchinger, N. Koutná, Z. Chen, Z. Zhang, P.H. Mayrhofer, D. Holec, M. Bartosik, Toughness enhancement in TiN/WN superlattice thin films, Acta Mat. 172, 2019, 18

Biography

Paul Mayrhofer is University Professor of Materials Science at the Institute of Materials Science and Technology, and chairs the Materials Science Division at the University TU Wien, Vienna, since 2012. He received a Dr. in 2001 and Habilitation in 2005 in Materials Science at the University of Leoben. Paul spent his post-doc and Erwin-Schrödinger-Fellowship at the University of Illinois at Urbana-Champaign, RTWH Aachen, and Linkoping University. Paul is currently Dean of Academic Affairs for Materials Science, and Mechanical and Industrial Engineering at TU Wien. Editor for Short Communications of Vacuum, and in the Editorial Board of Surface and Coatings Technology and Ceramics in Modern Technologies.

Paul has pioneered age hardening within hard ceramic thin films based on ternary nitrides and borides and is fascinated by phase transitions in general. His research activities focus on the development and characterization of vapor phase deposited nanostructured materials by a combination of computational and experimental material science. He won the prestigious START price of the Austrian Science Fund and served scientific societies in numerous appointed and elected positions such as being a member of the Young Academy of the Austrian Academy of Sciences, President of the Austrian Vacuum Society, Chair of the Advanced Surface Engineering Division of the American Vacuum Society (AVS). Paul is Fellow of AVS for Seminal contributions in the development of vapor phase deposited nanostructured materials and self-hardened protective coatings of ternary nitrides and borides. He has published more than 260 SCI listed papers in the general field of thin film materials science, with >10,600 citations to these (h-index of 54), and holds 13 patents regarding hard coatings.

Video Proceedings of Advanced Materials

Upcoming Congress