Video Article Open Access

ML based Texture Recognition Algorithms to Quantify Microstructure and Fracture in Metals

Ravi Kiran1,*, Dayakar Lavadiya Naik2

1Assistant Professor, North Dakota State University, Fargo, 58105, USA

2Graduate Research Assistant, North Dakota State University, Fargo, 58105, USA

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-02125 (2021)

DOI: 10.5185/vpoam.2021.02125

Publication Date (Web): 27 Mar 2021

Copyright © IAAM

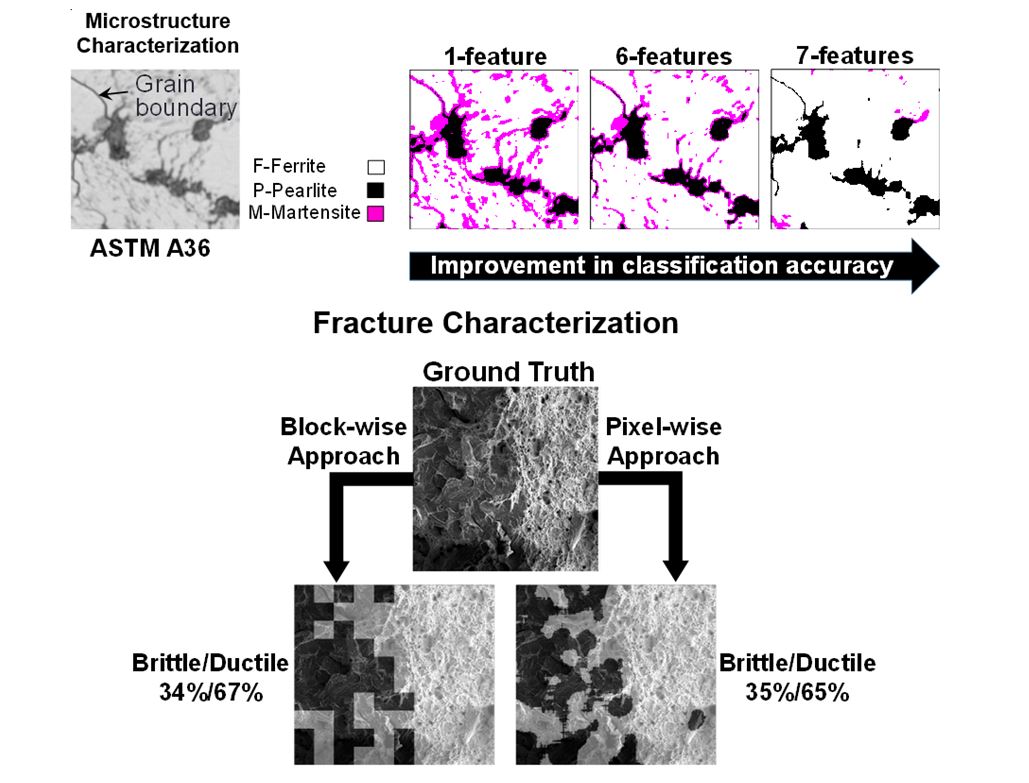

Graphical Abstract

Abstract

Owing to the latest developments in the field of microscopy, it is now possible to acquire a large number of detailed images to characterize phenomena that have a microstructural origin in metals. It is essential to automate microanalyses to utilize the advances in microscopy fully. Manual microanalyses are slow, cumbersome, and subjective. The goal of this lecture is to explore the potential of Machine Learning-based texture recognition algorithms to identify and quantify the 1) metallurgical phases [1], and 2) fracture type in structural steels [2] automatically and accurately from micrographs and fractographs, respectively. Metallurgical phase composition dictates the macroscopic mechanical properties of metals like strength and ductility and hence are important for evaluating microstructure-property relationships [3]. On the other hand, appropriate fracture models cannot be employed without identifying the specific fracture initiating mechanism in metals. In this study, we hypothesize that individual metallurgical phases and fracture mechanisms possess unique, distinguishable textural features and machine learning algorithms can be trained to recognize these textural characteristics. To prove this hypothesis, we identified and quantified the phase compositions in heat-treated ASTM A36 steel and mechanisms leading to fracture in ASTM A992 steel that are popularly used in construction industry. While the statistical properties of the grey level co-occurrence matrix (GLCM) are used as textural features for metallurgical phase identification, greyscale and rotation invariant Linear Binary Patterns (LBP) are employed to identify the fracture initiation mechanisms. About 735 data points that consisted of GLCM textural features are extracted from the micrographs are used to train four ML classifiers to identify the metallurgical phases in heat-treated ASTM A36 steel. Feature selection and ideal size of the window to extract textural features is evaluated to improve the prediction accuracy. The trained ML algorithms, unlike intensity-based algorithms, did not misclassify the grain boundaries. Furthermore, the end-user is not required to know the number of unique phases in the microstructure for using texture recognition algorithms. For the sake of fracture mechanism identification, 100 images are used to train a linear Machine Learning classifier. Block-wise and pixel-wise approaches are proposed for computational expediency and accuracy, respectively. The proposed Machine Learning based texture recognition algorithms were able to match the ground truth images for both metallurgical phase and fracture mechanism identification. In a nutshell, this study proves that the microstructural features in metals possess unique machine recognizable textures that can be employed for automatic microanalyses.

Keywords

Microstructure, metallurgical phases, ductile fracture, brittle fracture, and texture recognition algorithms.

Acknowledgement

The authors would like to acknowledge the financial support from the North Dakota Established Program to Stimulate Competitive Research (ND EPSCoR).

References

- D.L. Naik, H.U. Sajid, R. Kiran; Metals, 2019, 9, 546.

- D.L. Naik, R. Kiran; Engineering Fracture Mechanics, 2019, 219, 1066182.

- H.U. Sajid, D.L. Naik, R. Kiran; ASCE JMCE, 2020, 32 (6), 04020133-1-14.

Biography

Ravi Kiran is an assistant professor in the Civil and Environmental Engineering department at North Dakota State University (NDSU) and is the Principal Investigator (P.I.) for the Damage in Materials and Structures (DAMS) lab. Before this appointment, he was a postdoctoral researcher at Brown University. He received his Ph.D. in structural engineering from the University of Notre Dame in the year 2015. Among other awards, he received the 2019 NDSU College of Engineering Early Career Teaching Award, 2017 NDSU student success Impact award, 2014 O.H. Ammann structural engineering fellowship, and stood runner-up in the 2014 computational mechanics poster competition. Dr. Ravi's research interests lie in the broad areas of damage mechanics and Artificial Intelligence with applications in civil and transportation infrastructure. He co-authored 31 journal articles, presented his research work in over 30 international conference venues, and delivered 11 invited talks. He is an ad hoc reviewer for 27 journals and has served as an invited reviewer for funding agencies. He is an associate editor for ASCE Journal of Materials in Civil Engineering and served as Guest Editor for a special issue on Advances in Structural Steel Research published in MDPI Metals. He is a member of the American Institute of Steel Construction (AISC), American Concrete Institute (ACI), and the American Society of Civil Engineers (ASCE). He is a registered Professional Engineer in the state of Minnesota.

Video Proceedings of Advanced Materials

Upcoming Congress