Video Article Open Access

Complex-oxide AB2O4 Materials and their Applications: ZnGa2O4 as an Example

Dong-Sing Wuu1,*, Ray-Hua Horng2, Po-Wei Chen1, Po-Wen Hsiao1, Anoop Kumar Singh1, Mu-I Chen1, Shiau-Yuan Huang1

1Department of Materials Science and Engineering, National Chung Hsing University, 145, Xingda Rd., Taichung 40227, Taiwan

2Department of Electronics Engineering, National Chiao Tung University, 1001 University Rd., Hsinchu, 30010, Taiwan

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-02103 (2021)

DOI: 10.5185/vpoam.2021.02103

Publication Date (Web): 21 Mar 2021

Copyright © IAAM

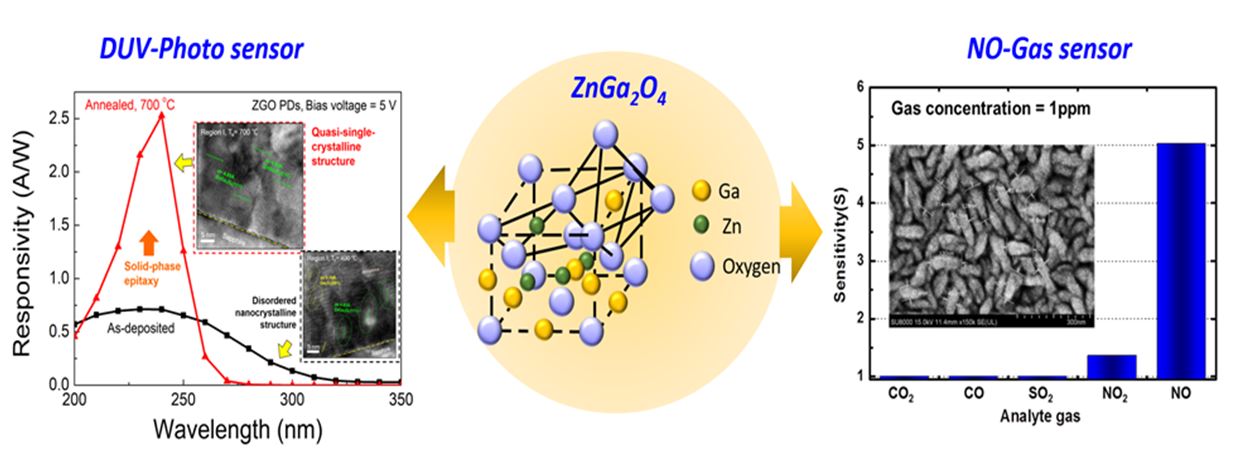

Graphical Abstract

Abstract

Complex oxide has multi-functional properties such as optoelectrical, ferroelectric, catalytic, and superconductive properties, leading to the extensive applications to the semiconductor and microelectronic field. The typical complex-oxides are multi-metal-oxide compound materials, which have the formula of ABO3 and AB2O4. The representative AB2O4 is the spinel material such as ZnAl2O4 and ZnGa2O4. The ZnGa2O4 material has wide bandgap and the chemically inert properties, which is one of the promising materials for deep-ultraviolet photodetectors (DUV PDs) and gas sensor applications. For deep-ultraviolet photodetector applications, the material with the bandgap above 4.4 eV can absorb the UV-C radiation and can neglect the visible light, which is suitable for employing as the DUV PDs with the high sensitivity [1]. The DUV PDs can be extensive applicated in the military for tracking missiles, the industry for detecting UV light source, the astronomy for analysing elements in the stellar atmosphere, and the environment for monitoring ozone and warning flame. The ZnGa2O4 thin film having a wide bandgap of 5.1 eV is suitable for DUV PD applications, which was deposited by using conventional radio-frequency (RF) magnetron sputtering. Since the Zn atoms can diffuse out of the film structure during the annealing, the ZnGa2O4 material is difficult to get the single-crystalline structure by using the sputtering method. In this study, the solid-phase epitaxy method is used for crystallizing the ZnGa2O4 structure via the rapid thermal annealing process. The disordered crystal-grains as incubated seeds are obtained in the as-deposited ZnGa2O4 film at the substrate temperature of 400 oC. Further annealing under the temperature of 700 oC in 1 min, the ZnGa2O4 film structure approaches the quasi-single-crystalline ZnGa2O4 structure, which is evidenced by checking the transmission electron microscopy. The responsivity of annealed ZnGa2O4 PDs can reach 2.53 A/W (at 240 nm and 5 V), which shows a relative enhancement of 256% compared with the as-deposited ZnGa2O4 PDs [2]. For gas sensor applications, nitric oxide (NO) is an extremely toxic oxidizing gas with a pungent odor. The ZnGa2O4 thin film was deposited by metalorganic chemical vapor deposition (MOCVD) with various temperatures from 25 °C to 300 °C. The gas sensor shows a great sensing property at 300 °C, which resulting in the sensitivity of 22.21 under the NO explosion of 6.25 ppm and its response time of 57 s. Besides, the sensitivities of 1.18, 1.27, 1.06, and 1.00 were obtained under the exposure to NO2 (500 ppb), SO2 (125 ppm), CO (125 ppm), and CO2 (1500 ppm), respectively [3]. These results imply that the ZnGa2O4 gas sensor not only has high sensitivity but also has great selectivity for NO gas. The ZnGa2O4 material possessed the multi-functional properties, which has a high potential for the internet of things (IoT) applications.

Keywords

Complex oxide; ZnGa2O4; quasi-single-crystalline; deep-ultraviolet photodetector; NO gas sensor.

Acknowledgement

This work was financially sponsored by the Ministry of Science and Technology (Taiwan) under Grant No. 108-2221-E-005-028-MY3. We thank to the financial support by the “Innovation and Development Center of Sustainable Agriculture” from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan, this work can be successfully accomplished.

References

- S.H. Yuan, S.L. Ou, S.Y. Huang, D.S. Wuu, ACS Applied Materials Interfaces, 2019, 11, 17563.

- P.W. Chen, S.Y. Huang, S.H. Yuan, Y.A. Chen, P.W. Hsiao, D.S. Wuu, Advanced Materials Interfaces, 2019, 6, 1901075.

- M.R. Wu, W.Z. Li, C.Y. Tung, C.Y. Huang, Y.H. Chiang, P.L. Liu, R.H. Horng, Scientific Reports, 2019, 9, 7459.

Biography

Dong-Sing Wuu received the Ph.D. degree in electrical engineering from National Sun Yat-Sen University, Taiwan in 1991. He had involved in the field of integrated optics and ink-jet print heads in Industry Technology Research Institute, Taiwan. From 2010 to 2016, he was elected as the 6th and 7th President of Da-Yeh University. He is currently a lifetime distinguished professor with the Department of Materials Science and Engineering, National Chung Hsing University, Taiwan. Dr. Wuu has contributed more than 300 SCI papers, 7 book chapters and over 150 patents in his fields of expertise. His current research interests include wide-bandgap oxides, thin-film technology, IOT sensing, photonic devices and displays. Prof. Wuu has been honored by the fellows of Institute of Physics (IOP), The Optical Society (OSA), The International Society for Optics and Photonics (SPIE), The Institution of Engineering and Technology (IET), The Australian Institute of Energy (AIE) and The Thin Films Society (TFS). In 2018, he has received the Outstanding Engineering Professor Award of the Chinese Institute of Engineers.

Video Proceedings of Advanced Materials

Upcoming Congress