Video Article Open Access

The Effect of Graphene on the Rheological Properties of Alumina and Zirconia Nanopowders

Dmitriy D.Titov*, Trusova E.A.

A.A. Baikov Institute of Metallurgy and Materials Science, Russian Academy of Sciences, Moscow, 119334, Russia

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-0172 (2021)

DOI: 10.5185/vpoam.2021.0172

Publication Date (Web): 27 Jan 2021

Copyright © IAAM

Graphical Abstract

Abstract

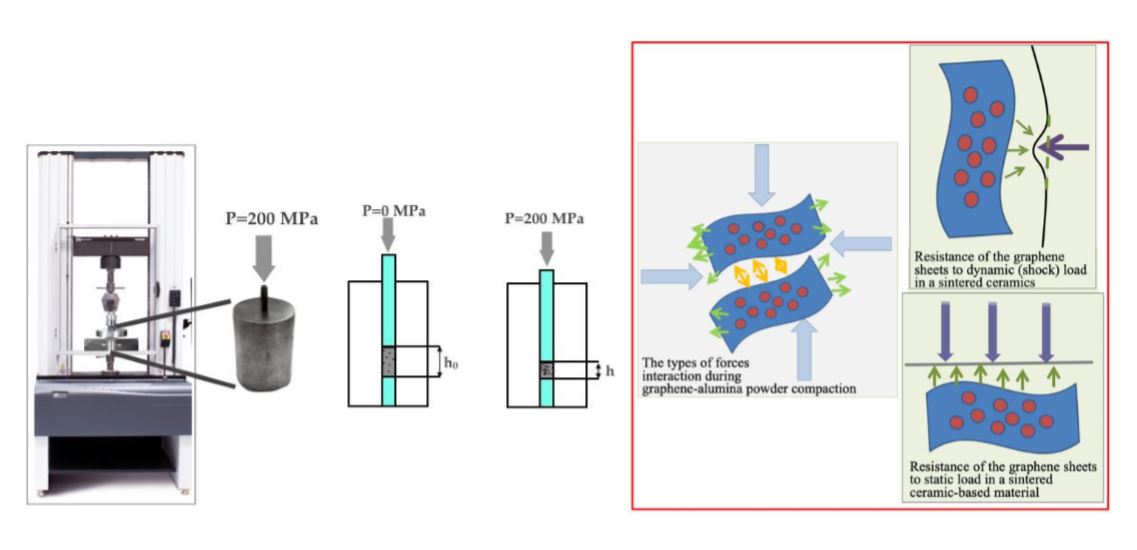

The use of nanostructured composite powders based on alumina or zirconia and graphene makes it possible to obtain ceramic materials with high density and electrical conductivity. They are necessary for the development of small-sized high-speed electronic devices with a wide range of functions and low energy consumption due to the presence of specific interactions in complex nanostructures and reduced energy loss to the environment. An original method for the synthesis of a chemically uniform composite powder based on oxygen-free graphene and nanostructured aluminium and zirconium oxides was developed at IMET RAS (Moscow). The uniqueness of this method lies in the combination of sol-gel synthesis and ultrasonic exfoliation of graphene sheets from the surface of synthetic graphite in an aqueous-organic colloid [1-3]. Synthesized graphene - metal oxide powders were characterized by XRD, TEM, HRTEM (EELS), vibrational spectroscopy, diffusion aerosol spectrometry and elemental analysis. It was shown that the method allows obtaining ultrafine dispersed metal (Zr and Al) oxides while avoiding graphene agglomeration in the bulk material. Lately our focus has been on rheological studies, which showed that even a low graphene content, 0.8-2.0 wt.%, provides a decrease in the compressibility of composites compared to pure metal oxides obtained under the same conditions.

The dependence of compressibility on stress was determined, compressibility modulus, ultimate strain values of the linear section and compressibility coefficient was calculated. A comprehensive comparative analysis of the results for composites and pure nanopowders of aluminium and zirconium oxides was carried out. At the initial stage, at low pressure, a linear increase in the strain value as a function of stress was observed, which is characteristic of the elastic strain region. Then, the curves bent due to the transition of the systems to the area of plastic deformation due to the generation of dislocations. In the case of a composite, this kink is due to a change in the mechanism that occurs at a slightly higher stress and a lower degree of deformation in comparison with pure oxide. Such an effect of graphene additives on rheological properties was observed in the case of graphene-containing composites based on both alumina and zirconia.

Compressibility parameters were calculated for graphene-alumina and graphene-zirconia composites, and they were compared with data for pure zirconia and alumina. Because the compressibility modulus is equal to the tangent of the angle of the linear section of the rheological curve, it has been determined that its value for the composite powder is more than doubled compared to pure metal oxide. For example, for a graphene-alumina composite, the limit value of linear strain is more than a quarter lower than this parameter for pure alumina. Also, the compressibility factor for this composite is 1.85 times smaller than for pure alumina. The results for the graphene-zirconia composite have a similar character: the compressibility modulus of the composite is one and a half times higher than that of the pure zirconia nanopowder; the ultimate strain of the composite decreased by 8% compared to pure nano zirconia; the compressibility coefficient of the composite also reduced by 42% compared with pure nano zirconia [4,5].

It was found that the elasticity of the obtained sintered composite material is higher than that of ceramics made of pure metal oxide. The results obtained allow us to consider our development to be promising for creating technology of fine-grained ceramics with improved mechanical properties, such as hardness, impact strength and bending strength.

Keywords

Graphene ceramics; rheology; compressibility modulus, nano zirconia composite, nano alumina composite.

Acknowledgement

The synthetic part of the work was carried out according to government assignment No. 075-00746-19-00. D.D. Titov and E.A. Trusova thank Russian Foundation for Basic Research (grant No. 19-03-00554_a) for financial support of research related to the complex characterization of the synthesized products.

References

- E.A. Trusova, K.V. Kotsareva, A.N. Kirichenko, S.S. Abramchuk, I.A. Perezhogin, Advances in Materials Science and Engineering, 2018, 11р, 6026437.

- E.A. Trusova, IOP Conference Series: Materials Science and Engineering, 2013, 47, 012043.

- E.A. Trusova, K.V. Kotsareva, A.N. Kirichenko, S.S. Abramchuk, A.A. Ashmarin, I.A. Perezhogin, Diamond and Related Materials, 2018, 85, 23.

- Trusova, E. A., Titov, D. D., Kirichenko, A. N., & Zorin, M. Y. New Journal of Chemistry, 2020 in press.

- Trusova, E. A., Titov, D. D., Kirichenko, A. N., Shelekhov, E. V., Trutnev, N. S., Afzal, A. M., & Perezhogin, I. A. Nanoscale Advances, 2020, 2, 182.

Biography

Dmitriy D. Titov is a chemist and received his doctoral degree from the Russian Academy of Sciences for the work in the oxygen-free ceramics based on MoSi2 in 2014. Since the graduate the Moscow State University, he works at the Baikov Institute of Metallurgy and Materials Science of RAS (IMET RAS). Now he is a senior scientist and leader of the group in IMET RAS. His current research is focused on the process of sintering ceramics: 1) analysis of rheological properties, the study of the method of synthesis of ceramic composites 2) comparison of the sintering process 3) analysis of the dynamic process occurring during shrinkage of ceramics (activation energy of the sintering process); 4) transparent ceramics. Today, a group led by Titov D.D. working on projects: 1) Sintering processes and phase formation study of multicomponent systems based on SHS MoSi2-NbSi2 ceramic to develop novel high-temperature heater and coating layer; 2) A method development for producing ceramic materials based on xAl2O3-yMgO-zY2O3, MgAl2O4 and Y3Al5O12, designed to provide molybdenum-silicide ceramics resistant to oxidation: parameters and mechanism of sintering organoalumoxane oligomers; in a collaboration he works at the project: 3) Composite nanostructures based on graphene and Ce-, Zn-, Zr-oxides: synthesis, physicochemical properties, use for the development of functional fine-grained ceramics of a wide application range. In 2019, he received an award «Moscow Government Prize for Young Scientists».

Video Proceedings of Advanced Materials

Upcoming Congress