Video Article Open Access

Centrifugal Nozzleless Spinning - Alternative Technology to Produce Nanofiber Constructs

Milos Beran*, Josef Drahorad, Ondrej Vltavsky

Food Research Institute Prague, Radiova 7, Prague, CZ10200, Czech Republic

Vid. Proc. Adv. Mater., Volume 2, Article ID 2021-0160 (2021)

DOI: 10.5185/vpoam.2021.0160

Publication Date (Web): 09 Feb 2021

Copyright © IAAM

Graphical Abstract

Abstract

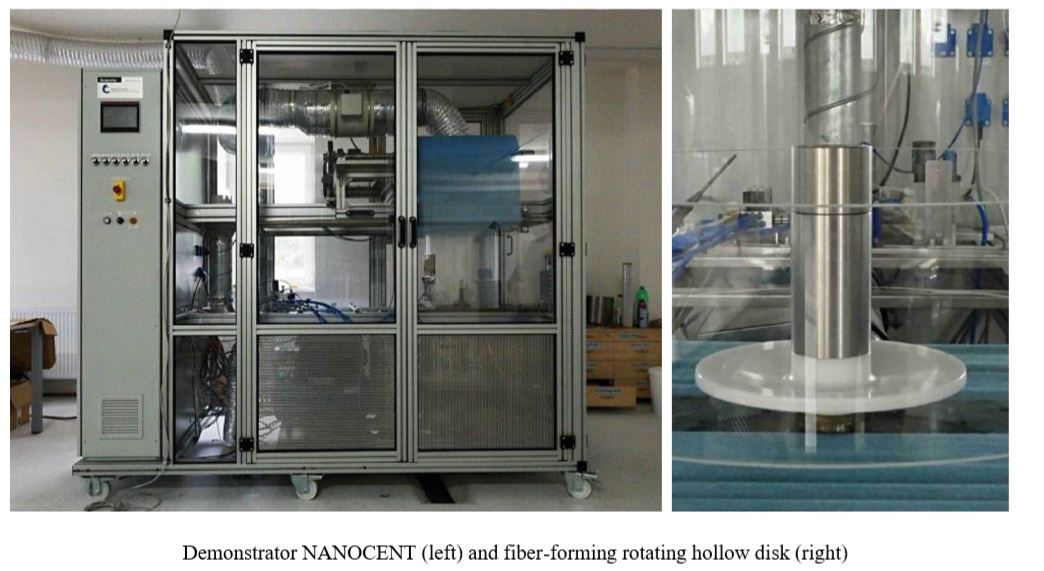

While most nanofibers are produced using electrospinning, this technique suffers from several drawbacks, such as the requirement for specialized equipment, high electrical potential, and electrically conductive targets. Consequently, recent years have seen the increasing emergence of novel strategies in generating nanofibers in a larger scale and higher throughput manner. The centrifugal spinning is simple, cheap and highly productive technology for nanofiber production. In principle, the drawing of solution filament into nanofibers using centrifugal spinning is achieved through the controlled manipulation of centrifugal force, viscoelasticity, and mass transfer characteristics of the spinning solutions. Engineering efforts of researches of the Food research institute Prague and the Czech Technical University in the field the centrifugal nozzleless spinning led to introduction of a pilot plant demonstrator NANOCENT. The main advantages of the demonstrator are lower investment cost - thanks to simpler construction compared to widely used electrospinning equipments, higher production speed, new application possibilities and easy maintenance. The centrifugal nozzleless spinning is especially suitable to produce submicron fibers from polymeric solutions in highly volatile solvents, such as chloroform, dichlormethane, tetrahydrfuran, or acetone. To date, submicron fibers have been prepared from polystyrene, polyuretane and biodegradable polyesters, such as polyhydroxybutyrate, polylactide, polycaprolactone, or polybutylensuccinate. The products are in form of 3D structures or nanofiber membranes. The nanofiber membranes and 3D constructs been tested for different applications. Filtration efficiencies for air aerosols were outstanding. Different active inserts were added to the solutions before the spinning process, such as inorganic nanoparticles, organic precursors of metal oxides, antimicrobial and wound healing compounds or photocatalytic phthalocyanines. Centrifugally spun submicron fiber membranes and 3D constructs are especially suitable for biomedical applications, such as tissue engineering, drug delivery, and wound or burn dressing.

Keywords

Nanofibers, 3D constructs, centrifugal nozzleless spinning.

Acknowledgement

This work was supported by the research grants TH03020466 of the Technology agency of the Czech Republic and the Institutional Development Fund of FRIP provided by the Ministry of Agriculture of the Czech Republic.

Biography

Milos Beran obtained Dipl. Eng. in the Institute of Chem. Technology, Prague - Department of Food Technology in 1985. Since 1985 he has been employed in the Food Research Institute, Prague, Department of Quality Features and Microbial Products. He has been interested in the fields of biotechnology, fermentation technologies, enzymology, separation technologies, analytical chemistry, food / medical nanotechnologies and material research. He was a successful leader of many national research projects in the field of food technologies and biotechnologies. He is engaged mainly in applied research (17 Patents, 62 Utility Models).

Video Proceedings of Advanced Materials

Upcoming Congress