Video Article Open Access

AdSCR systems (NOx Adsorption + Selective Catalytic Reduction) to minimize cold start NOx emissions from Diesel engines

Federica Gramigni, Nicole Daniela Nasello, Tommaso Selleri, Isabella Nova*, Enrico Tronconi

Politecnico di Milano, Dipartimento di Energia, Milano, 20156, Italy

Vid. Proc. Adv. Mater., Volume 1, Article ID 2020-0841 (2020)

DOI: 10.5185/vpoam.2020.0841

Publication Date (Web): 10 Nov 2020

Copyright © IAAM

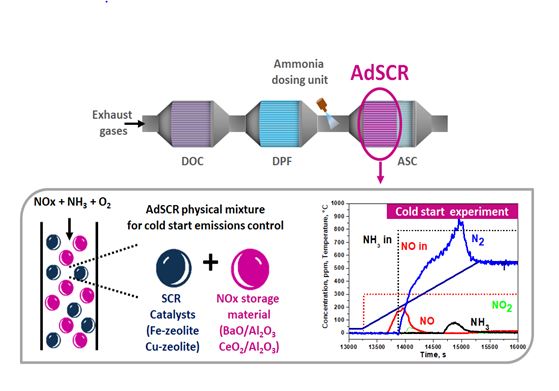

Graphical Abstract

Abstract

Most of NOx emissions from Diesel engines occurs during the cold-start period, due to poor activity of SCR converters and to the urea injection temperature threshold [1]. The present work presents a novel multifunctional catalyst able to minimize the release of NOx at low temperature [2-4]. The strategy of the AdSCR system is to add a storage functionality to a state-of-the-art SCR catalyst, allowing both the capture of NOx at room temperature, and the direct reduction of the stored NOx at higher temperatures in a single device. Thanks to its PGM-free formulation, it can replace conventional SCR converters without modifications of the aftertreatment configuration. An experimental investigation was carried out over different samples, prepared by physically mixing a commercial SCR catalyst (Cu-CHA or Fe-ZSM5) and a NOx storage material (BaO/Al2O3 or CeO2/Al2O3). First, NO (500 ppm) + O2 (8%) isothermal adsorption + TPD experiments were performed to estimate the NOx storage capacity of each catalytic system. Then, the dual functionality of such physical mixtures was proved by means of cold start experiments: NO (300 ppm) was fed at room temperature, followed by a T-ramp (15 °C/min); when the temperature reached 170°C (here regarded as a T-threshold for urea injection), NH3 (800 ppm) was cofed to the reactor to start the SCR reactions. Different runs have been performed to study the effect of the feed composition (presence of H2O and CO2) and of preadsorbed ammonia on AdSCR transient behaviour.The results indicated that AdSCR systems are able to adsorb NO in O2 already at low temperature. In this regard, Cu-CHA + BaO/Al2O3 systems showed the best performances. In cold-start runs under dry conditions: (1) after the NO step feed, the NO outlet concentration exhibited a long dead time (420 s) before NOx breakthrough; (2) the overall engine-out NOx were reduced by 93% before NH3 injection; (3) as soon as NH3 was fed, a huge peak of N2 (900 ppm) was released and the NO concentration started to decrease due to the onset of the Standard SCR reaction. Interestingly, additional data showed that the presence of preadsorbed ammonia can even enhance the low temperature SCR activity, resulting in the light-off of nitrogen production already at 80°C. Dedicated tests also showed a negative impact of water and CO2 on the AdSCR performances; however, such an effect could be counterbalanced by optimizing the ratio between the NOx storage material and the SCR catalyst, and by selecting NOx storage materials more tolerant to CO2 (such as CeO2).These promising results may warrant further studies aimed at investigating the new AdSCR concept.

Keywords

Cold start; NOx adsorber; NH3-SCR, AdSCR.

References

- J. Lee, Y. Ryou, S.J. Cho, H. Lee, C.H. Kim Appl. Catal. B., 2018, 226, 71.

- T. Selleri, F. Gramigni, I. Nova, E. Tronconi, S. Dieterich, M. Weibel, V. Schmeisser Catal. Sci. Technol., 2018, 8, 2467.

- F. Gramigni, T. Selleri, I. Nova, E. Tronconi, S. Dieterich, M. Weibel, V. Schmeisser, Top. Catal., 2019, 62, 3.

- Simone Dieterich, Federica Gramigni, Isabella Nova, Volker Schmeißer, Tommaso Selleri, Enrico Tronconi, Michel Weibel, “Abgasnachbehandlungseinrichtung für ein Kraftfahrzeug mit einem Katalysator, welcher wenigstens ein SCR-Material und wenigstens ein NOx-Speicher-Material aufweist, und Verfahren zum Betreiben einer solchen Abgasnachbehandlungseinrichtung" International patent application PCT/EP2019/081867 (November 20, 2019) claiming priority of German patent application No. 10 2018 009 233.0 filed on November 26, 2018.

Biography

Isabella Nova is full Professor in Industrial Chemistry at the Department of Energy, Politecnico of Milan, Italy. She has got her Degree in Chemical Engineering (Politecnico di Milano, 1996), her P.h.D.in Industrial Chemistry (1999) from university of Milano. Isabella Nova’s research work is focused on catalytic technologies for emission control of lean burn exhausts (Selective Catalytic Reduction of NOx by NH3 and SDPF (SCR+Diesel Particulate Filter), NOx Storage-Reduction, both for mobile and stationary applications), and on new photo-electrochemical processes for the production of clean energy, such as the water splitting, and CO2 conversion in fuels and chemicals. She has co-authored over 150 publications on national and international journals in the fields of Chemical Reaction Engineering and Heterogeneous Catalysis and three national and international patents.

Video Proceedings of Advanced Materials

Upcoming Congress