Video Article Open Access

Highly Sensitive Hydrogen Gas Sensor based on a MoS2-Pt Nanoparticle Composite

Sheng-Yuan Chu*, Sandeep Reddy Gottam, Chi-Ting Tsai, Li-Wen Wang

Department of Electrical Engineering, National Cheng Kung University, Tainan, 701, Taiwan

Vid. Proc. Adv. Mater., Volume 1, Article ID 2020-0828 (2020)

DOI: 10.5185/vpoam.2020.0828

Publication Date (Web): 02 Nov 2020

Copyright © IAAM

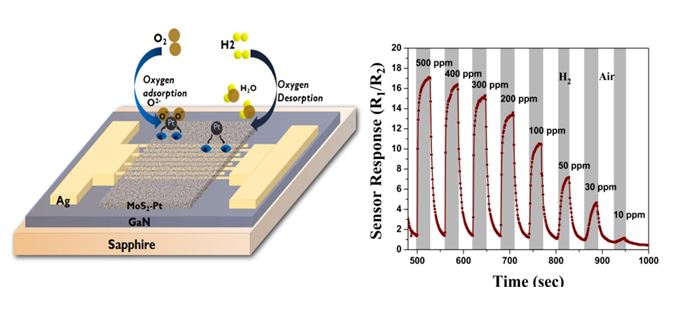

Graphical Abstract

Abstract

A highly sensitive hydrogen gas sensor composed of an MoS2-Pt nanoparticle thin film as the active layer is introduced. A hydrogen gas sensor with high sensitivity, high resistance change and fast response and recovery time are of immediate interest in the modern world. Metallization or additional doping of metal ions to these sulphides with a porous structure [1] in the sensing layer is the primary strategy [2] to improve the surface area and thus improve the sensing ability. The draw backs discovered by researchers working on MoS2 based H2 gas sensors are that they have an unstable base line, poor sensitivity, and poor response and recovery times [3]. In this work, we solved these issues by using an MoS2–Pt nanoparticle composite and achieved high sensor response and ultrafast response and recovery rates with good stability and selectivity. The sensor achieved ultra-fast response and recovery rates of 8 s and 19 s, respectively, for 100 ppm of H2. The MoS2-Pt composite film exhibits a high sensor response (R1/R2) of 10 when exposed to 100 ppm of H2 gas, which outperforms the existing metal sulfide-based sensors. The stability of the device over a period of 70 days and the selectivity of the device is outstanding. A plausible mechanism for the MoS2-Pt based H2 gas sensor is discussed. Furthermore, the sensitivity, response and recovery rates for various concentrations of H2 gas are studied. The sensor response is exceptionally promising. This sensor with metal sulfide-platinum composite active layers can be applied in the sensor field to amplify the sensing performance.

Acknowledgement

This research was, in part, supported by the Ministry of Science and Technology, Taiwan, R.O.C., Aim for the Top University Project for National Cheng Kung University. The authors gratefully acknowledge the financial support provided by the Ministry of Science and Technology, Taiwan (grants MOST 106-2221-E-006 -226).

References

- M. Tiemann, Porous metal oxides as gas sensors, Chem. A Eur. J., 2007, 13, 8376–8388.

- J.L. Rowsell, O.M. Yaghi, Strategies for hydrogen storage in metal–organic frameworks, Angew. Chem. Int. Ed., 2005, 44, 4670-4679.

- M. Donarelli, S. Prezioso, F. Perrozzi, F. Bisti, M. Nardone, L. Giancaterini, C. Cantalini, L. Ottaviano, Response to NO2 and other gases of resistive chemically exfoliated MoS2-based gas sensors, Sens. Actuators, B, 2015, 207, 602-613.

Biography

Sheng-Yuan Chu is Distinguished Professor at the Electrical engineering department of National Cheng Kung University in Taiwan and he is the head of Acoustic & Electric-Optical Materials Lab. He earns his undergraduate degree from National Tsing -Hua University and his Master’s and PhD degrees from The Pennsylvania State University in The United States. Currently, his group specifically explores the research regarding Electronic & Ceramic Materials / Devices, MEMS Devices, Nano-optoelectric Materials & Display Devices, Nano-imprinting Technology, and Organic Light-Emitting Devices, Semiconductor thin films and devices. Dr. Chu’s teaching interests include Special Topics of Acoustic & Electric-Optical Devices and Electronic Circuits Experiments. He achieved National Science Council Type A Research Award and Taiwan Vacuum Annual Conference Paper Excellence Award in 2013 for the outstanding research work. He achieved his 26 years of his teaching experience by starting as an Associate Professor in Chien-Kuo Technology University and then in Da-Yeh University. He started his carrer in the Department of Electrical Engineering, National Cheng Kung University in 1998 as an Assistant professor and the journey began with promotions and currently working as a Distinguished Professor. He worked as the Director of National Cheng Kung University Promotion Education Center and also as a Leader of Academic Service Group of National Cheng Kung University. The native students and the International students from various countries work together in his research group with innovative ideas and implementation plans. Professor Chu resides with his family in Tainan, Taiwan. In his free time he plays Table Tennis and explores the city for good traditional cuisine and art museum.

Video Proceedings of Advanced Materials

Upcoming Congress