Video Article Open Access

Thermochemical processing of Li-Ion battery black matter

Stefan Windisch, Alexandra Holzer, Christoph Ponak, Harald Raupenstrauch*

AMontanuniversitaet Leoben, Leoben, 8700, Austria

Vid. Proc. Adv. Mater., Volume 1, Article ID 2020-0804 (2020)

DOI: 10.5185/vpoam.2020.0804

Publication Date (Web): 05 Aug 2020

Copyright © IAAM

Graphical Abstract

Abstract

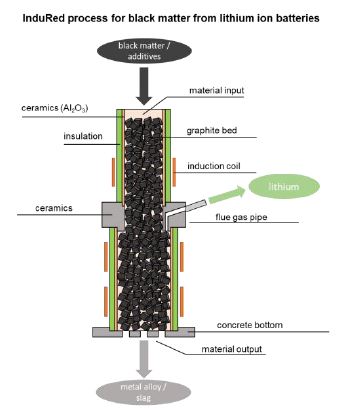

The versatility of lithium ion batteries (LIBs), which is powered by intense research activities and a constant pursuit of improvements, enables their usability in various applications on the one hand but also has its downside, since efficient waste management and recycling becomes difficult for hardly predictable waste streams with fluctuating chemical compositions. [1, 2] Nevertheless, due to the valuable and partly critical raw materials that are used for the cathode materials of lithium ion batteries, their recycling is not only necessary to reach sustainability goals and to ensure future raw material supply but can also be a technological challenge, which is economically worth going for. [3] A new approach on pyrometallurgical metal recovery from black matter, a product of the pre-processing of spent LIBs, is the application of the so-called InduRed reactor. With its inductively heated carbon bed that offers a large reaction surface and enables highly reducing conditions, the simultaneous recovery of nickel, cobalt, manganese, phosphorus and lithium shall be achieved. The corresponding research project in a first step investigates the behaviour of currently used pure cathode materials like NCA, NMC in different variations, LCO as well as LFP at high temperatures and under reducing conditions for which highly reactive carbon powder is added. For this purpose, heating microscope experiments as well as thermogravimetric and differential calorimetry analyses under inert and reducing conditions have been conducted. The experiments and analyses have also been carried out for black matter from a battery pre-processing step and the results of both experimental series were compared. The findings of these preliminary experiments have then been used to design an experiment in the so-called InduMelt plant, which is a discontinuous lab-scale reactor prototype that is based on the InduRed concept. It could be seen that first changes in the materials occur at temperatures of about 800°C when carbon was added, which might be caused by reduction reactions of nickel or cobalt compounds. The formation of a metal phase is affirmed by melting processes that can be observed at temperatures of around 1500°C. The results so far also show that the behaviour of the black matter from the pre-processing differs significantly from the pure cathode materials, which indicates that impurities like residues of copper or aluminium conductor foils have a big influence that must be investigated in the course of the research project. In experiments in the InduMelt plant, lithium removal rates of more than 89% have been reached in the test with NMC 111 and a metal alloy of nickel, cobalt and manganese could be obtained. The number of experiments still has to be increased in order to reproduce these values. At present, however, the qualitative result of gaseous Li removal is reaffirmed and is a distinct characteristic of the applied reactor. In conclusion, it can be said that the major findings of the research activity so far and especially the lithium removal rates are very promising. The further research work concentrates on the investigation of the occurring reactions regarding their energy demand and on the evaluation of necessary additional modifications of the black matter to match the requirements of the desired recycling process.

Keywords

Lithium ion batteries, sustainability, metal recycling, high temperature process engineering.

References

- Korthauer, R. (Ed.), Handbuch Lithium-Ionen-Batterien, Berlin, Heidelberg, s.l., Springer Berlin Heidelberg 2013

- Chemali, E., Preindl M., Malysz, P. and Emadi A., Electrochemical and Electrostatic Energy Storage and Management Systems for Electric Drive Vehicles: State-of-the-Art Review and Future Trends, IEEE J. Emerg. Sel. Topics Power Electron 4, 2016, 3, 1117–1134.

- Baes, K., Kolk M., Carlot F., Merhaba A. and Ito Y., , Future of batteries, 2018, available online at https://www.adlittle.com/sites/default/files

/viewpoints/adl_future_of_batteries-min.pdf

Biography

Harald Raupenstrauch was born in Austria in 1961 and after completing a technical high school he studied chemical process engineering at Graz University of Technology. He completed his doctorate in chemical and process engineering in 1991 and his habilitation in 1997, both at Graz University of Technology. The main focus of his scientific work was the mathematical modeling of gas-solid reactions at high temperatures. He spent about two years as visiting professor at Queen’s University of Belfast, Northern Ireland, Technical University of Delft, The Netherlands and Rutgers University, The State University of New Jersey, USA. Since 2007 he is full professor at Montanuniversitaet Leoben, Austria, where he owns the Chair of Thermal Processing Technology, and where he is head of the Department of Environmental and Energy Process Technology. In 2017 and 2018 he was Visiting Professor at the University of Zambia, Zambia as well as at the University of Lucerne, Switzerland. With his group he has developed several novel processes for the recovery of phosphorus and metals like iron, zinc, chromium, copper, cobalt, etc. from steel mill dusts, metallurgical slags, sewage sludge ashes and most recently Li-ion batteries. The main focus in this context are inductively heated packed beds as well as dust reactions in a flash-reactor at up to 1900°C. Related to processing reactive materials, investigations regarding safety relevant parameters concerning dust explosion and spontaneous ignition are part of this working area. His industrial partners have their background mainly in the metallurgical field, but also in the area of cement and glass production, with the focus being always on the recovery of valuable elements in order to improve resource efficiency and to create materials with optimized properties.

Video Proceedings of Advanced Materials

Upcoming Congress