Video Article Open Access

Novel Physical Hydrogels with Aromatic Pseudo Polypeptide Moieties

Lukas Hahn1,2,*, Stefan Forster1, Benedikt Sochor3,4, Robert Luxenhofer1,5

1Functional Polymer Materials, Chair for Advanced Materials Synthesis, Institute for Functional Materials and Biofabrication, Department of Chemistry and Pharmacy, Julius-Maximilians-University Würzburg, Röntgenring 11, 97070 Würzburg, Germany

2Institute for Pharmacy and Food Chemistry, Julius-Maximilians-University Würzburg, 97074 Würzburg, Germany

3Chair for X-Ray Microscopy, Julius-Maximilians-University Würzburg, Josef-Martin-Weg 63, 97074 Würzburg, Germany

4Deutsches Elektronen-Synchrotron (DESY), Photon Science, Notkestraße, 22607, Hamburg

5Soft Matter Chemistry, Department of Chemistry and Helsinki Institute of Sustainability Science, Faculty of Science, University of Helsinki, P.O. Box 55, 00014 Helsinki, Finland

Vid. Proc. Adv. Mater., Volume 3, Article ID 2203267 (2022)

DOI: 10.5185/vpoam.2022.03267

Publication Date (Web): 22 Jul 2022

Copyright © IAAM

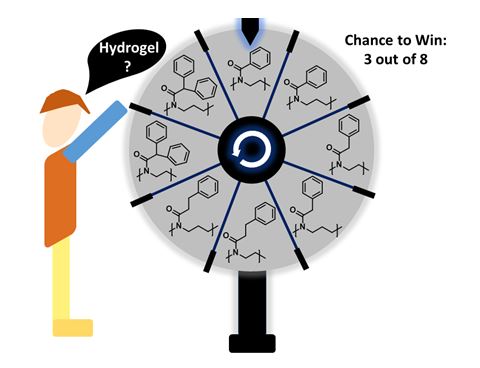

Graphical Abstract

Abstract

Biomimetic polymers are important components in several biomedical research areas such as drug delivery, tissue engineering and biofabrication. The cytocompatible polymer classes of poly(2-oxazolines) (POx) and poly(2-oxazines) (POzi), which are referred as pseudo polypeptides, gained huge attention as biomaterials in the last 10 years and in particular since first clinical trials of POx-drug conjugates are under way. The tailor-made polymers exhibit tunable properties such as solubility and self-assembly in aqueous environment, which makes this family of polymers promising alternatives to the widely used polyethylene glycol (PEG), the gold standard hydrophilic biomaterial.

For decades, to study amphiphilic self-assembly one dominant aromatic hydrophobic building block was poly(2-phenyl-2-oxazoline) (PPheOx). We systematically introduced a range of novel aromatic B blocks in POx/POzi based ABA type amphiphiles. The effect of the polymer backbone (POx vs POzi) and aromatic sidechain (phenyl→benzyl→phenethyl→benzhydryl) on the self-assembly at different concentrations and temperatures were studied. Interestingly, three unique inverse thermogelling hydrogel platforms with different gel properties originated from different gelation mechanisms were discovered. In brief, the hydrogels were formed by three dimensional arrangements of supramolecular architectures such as the entanglement of worm-like micelles1, the correlation of spherical micelles2, and fused micellar aggregates3. The formation of worm-like micelles was further studied on the molecular level. In the hydrogel state, specific interactions between the hydrophilic A blocks and the hydrophobic and aromatic B blocks induced the formation of worm-like micelles by reducing the volume fraction of the hydrophilic shell. This inverse thermogelling hydrogels opens new avenues to control and design macromolecular self-assembly to induce hydrogel formation.

Since the presented hydrogels are based on relatively weak interactions, leading to pronounced shear-thinning, these systems are ideally suited for extrusion-based 3D printing. In addition to initial printing experiments, the rheological properties, which have a particular influence on the printing outcome, were evaluated. Surpassing the yield point, all presented hydrogels showed pronounced shear-thinning properties, which is considered as one of the most important material property for the printing process. After the deformation, the hydrogels recovered very quickly, which is why defined structures could be printed. In addition, it was shown that the hydrogels can be used as printing additives to manufacture otherwise unprintable materials. In the future, in addition to simple blending to other materials, the ease of introducing additional chemical crosslinking points, as recently demonstrated for a thermogelling POx/POzi system, via post-polymerization modification5 can be used for more advanced applications in biofabrication.

Keywords

Poly(2-oxazoline); aromatic moieties; self-assembly; hydrogels; bioprinting.

Acknowledgement

Supported by the German Research Foundation-Project Number 326998133-TRR225 (subproject A03).

References

- Hahn, L.; Maier, M.; Stahlhut, P.; Beudert, M.; Flegler, V.; Forster, S.; Altmann, A.; Töppke, F.; Fischer, K.; Seiffert, S.; Böttcher, B.; Lühmann, T.; Luxenhofer, R.; ACS Applied Materials and Interfaces, 2020, 12(11), 12445-12456.

- Hahn, L.; Karakaya, E.; Zorn, T.; Sochor, B.; Maier, M.; Stahlhut, P.; Forster, S.; Fischer, K.; Seiffert, S.; Pöppler, A.C.; Detsch, R.; Luxenhofer, R.; Biomacromolecules, 2021, 22(7), 3017.

- Hahn, L.; Keßler, L.; Polzin, L.; Fritze, L.; Forster, S.; Helten, H.; Luxenhofer, R.; Macromolecular Chemistry and Physics, 2021, 22(7).

- Hahn*, L.; Beudert*, M.; Gutmann, M.; Keßler, L.; Stahlhut, P.; Fischer, L.; Karakaya, E.; Lorson, T.; Thievessen, I.; Detsch, R.; Lühmann, T.; Luxenhofer, R.; Macromolecular Bioscience, 2021, DOI: 10.1002/mabi.202100122.

Biography

Lukas Hahn studied Biochemistry (Bachelor of Science; Julius-Maximilians University Würzburg, Germany) and Natural Products and Drug Chemistry (Master of Science; University Bayreuth, Germany). After a temporary employment at BASF Coatings, he joined the research group of Prof. Luxenhofer (Functional Polymer Materials (Würzburg) and Soft Matter Chemistry (Helsinki)) to work on various topics in applied polymer chemistry with the focus on drug encapsulation and biofabrication.

Video Proceedings of Advanced Materials

Upcoming Congress